Page 416 - Advances in Eco-Fuels for a Sustainable Environment

P. 416

Engine modification for alternative fuels usage in diesel engine 369

Biodiesel

0

100

10

90

20

80

30

70

40

60

50

50

60

40

70

30

80

20

90

10

100

0

Diesel 0 10 20 30 40 50 60 70 80 90 100 Hexanol

Good miscibility and high flash and fire point

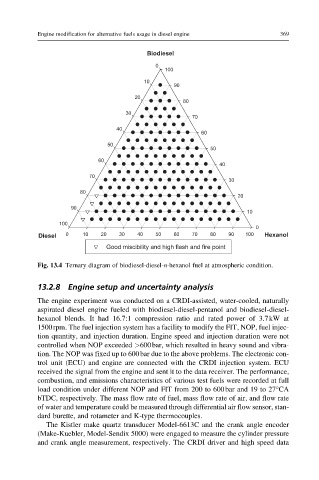

Fig. 13.4 Ternary diagram of biodiesel-diesel-n-hexanol fuel at atmospheric condition.

13.2.8 Engine setup and uncertainty analysis

The engine experiment was conducted on a CRDI-assisted, water-cooled, naturally

aspirated diesel engine fueled with biodiesel-diesel-pentanol and biodiesel-diesel-

hexanol blends. It had 16.7:1 compression ratio and rated power of 3.7kW at

1500rpm. The fuel injection system has a facility to modify the FIT, NOP, fuel injec-

tion quantity, and injection duration. Engine speed and injection duration were not

controlled when NOP exceeded >600bar, which resulted in heavy sound and vibra-

tion. The NOP was fixed up to 600bar due to the above problems. The electronic con-

trol unit (ECU) and engine are connected with the CRDI injection system. ECU

received the signal from the engine and sent it to the data receiver. The performance,

combustion, and emissions characteristics of various test fuels were recorded at full

load condition under different NOP and FIT from 200 to 600bar and 19 to 27°CA

bTDC, respectively. The mass flow rate of fuel, mass flow rate of air, and flow rate

of water and temperature could be measured through differential air flow sensor, stan-

dard burette, and rotameter and K-type thermocouples.

The Kistler make quartz transducer Model-6613C and the crank angle encoder

(Make-Kuebler, Model-Sendix 5000) were engaged to measure the cylinder pressure

and crank angle measurement, respectively. The CRDI driver and high speed data