Page 65 - Air and Gas Drilling Manual

P. 65

Chapter 2: Surface Equipment 2-15

rams on the top and a blind ram on the bottom. The two pipe rams allow some

flexibility in carrying out well control when drilling deep wells with a tapered drill

string and when placing a liner string in an air or gas drilled well. This BOP stack

is fitted with a rotating head flange connected to the top pipe ram blowout preventer.

This stack can be configured for the recovery of oil and natural gas deposits with

static bottomhole pressures of up to 5,000 psi.

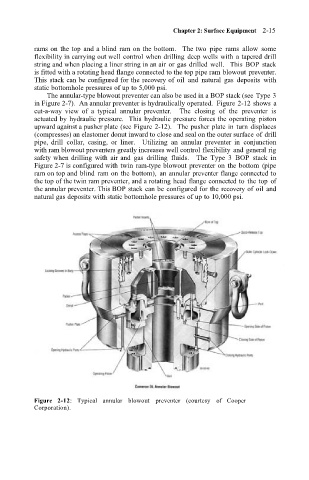

The annular-type blowout preventer can also be used in a BOP stack (see Type 3

in Figure 2-7). An annular preventer is hydraulically operated. Figure 2-12 shows a

cut-a-way view of a typical annular preventer. The closing of the preventer is

actuated by hydraulic pressure. This hydraulic pressure forces the operating piston

upward against a pusher plate (see Figure 2-12). The pusher plate in turn displaces

(compresses) an elastomer donut inward to close and seal on the outer surface of drill

pipe, drill collar, casing, or liner. Utilizing an annular preventer in conjunction

with ram blowout preventers greatly increases well control flexibility and general rig

safety when drilling with air and gas drilling fluids. The Type 3 BOP stack in

Figure 2-7 is configured with twin ram-type blowout preventer on the bottom (pipe

ram on top and blind ram on the bottom), an annular preventer flange connected to

the top of the twin ram preventer, and a rotating head flange connected to the top of

the annular preventer. This BOP stack can be configured for the recovery of oil and

natural gas deposits with static bottomhole pressures of up to 10,000 psi.

Figure 2-12: Typical annular blowout preventer (courtesy of Cooper Cameron

Corporation).