Page 120 - Analysis and Design of Machine Elements

P. 120

Analysis and Design of Machine Elements

98

(a) (b)

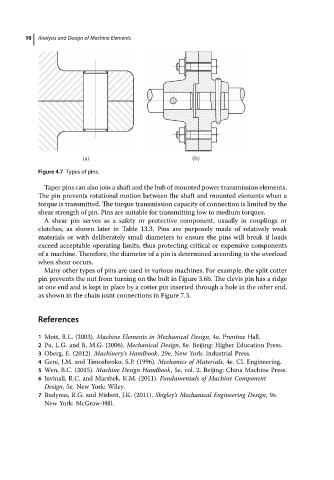

Figure 4.7 Types of pins.

Taper pins can also join a shaft and the hub of mounted power transmission elements.

The pinpreventsrotationalmotionbetween theshaft andmountedelementswhena

torque is transmitted. The torque transmission capacity of connection is limited by the

shear strength of pin. Pins are suitable for transmitting low to medium torques.

A shear pin serves as a safety or protective component, usually in couplings or

clutches, as shown later in Table 13.3. Pins are purposely made of relatively weak

materials or with deliberately small diameters to ensure the pins will break if loads

exceed acceptable operating limits, thus protecting critical or expensive components

of a machine. Therefore, the diameter of a pin is determined according to the overload

when shear occurs.

Many other types of pins are used in various machines. For example, the split cotter

pin prevents the nut from turning on the bolt in Figure 3.6b. The clevis pin has a ridge

at one end and is kept in place by a cotter pin inserted through a hole in the other end,

as shown in the chain joint connections in Figure 7.3.

References

1 Mott, R.L. (2003). Machine Elements in Mechanical Design, 4e. Prentice Hall.

2 Pu, L.G. and Ji, M.G. (2006). Mechanical Design, 8e. Beijing: Higher Education Press.

3 Oberg, E. (2012). Machinery’s Handbook, 29e. New York: Industrial Press.

4 Gere, J.M. and Timoshenko, S.P. (1996). Mechanics of Materials, 4e. CL Engineering.

5 Wen, B.C. (2015). Machine Design Handbook, 5e, vol. 2. Beijing: China Machine Press.

6 Juvinall, R.C. and Marshek, K.M. (2011). Fundamentals of Machine Component

Design, 5e. New York: Wiley.

7 Budynas, R.G. and Nisbett, J.K. (2011). Shigley’s Mechanical Engineering Design,9e.

New York: McGraw-Hill.