Page 117 - Analysis and Design of Machine Elements

P. 117

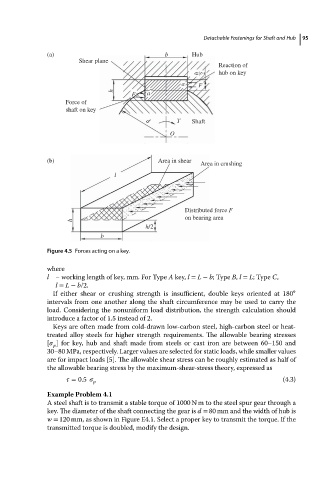

(a) b Hub Detachable Fastenings for Shaft and Hub 95

Shear plane

Reaction of

h 2 hub on key

a F

h

F a

Force of

shaft on key

d T Shaft

O

(b) Area in shear

Area in crushing

l

Distributed force F

on bearing area

h

h/2

b

Figure 4.5 Forces acting on a key.

where

l – working length of key, mm. For Type A key, l = L − b;Type B, l = L;Type C,

l = L − b/2.

If either shear or crushing strength is insufficient, double keys oriented at 180 ∘

intervals from one another along the shaft circumference may be used to carry the

load. Considering the nonuniform load distribution, the strength calculation should

introduce a factor of 1.5 instead of 2.

Keys are often made from cold-drawn low-carbon steel, high-carbon steel or heat-

treated alloy steels for higher strength requirements. The allowable bearing stresses

[ ] for key, hub and shaft made from steels or cast iron are between 60–150 and

p

30–80 MPa, respectively. Larger values are selected for static loads, while smaller values

are for impact loads [5]. The allowable shear stress can be roughly estimated as half of

the allowable bearing stress by the maximum-shear-stress theory, expressed as

= 0.5 (4.3)

p

Example Problem 4.1

A steel shaft is to transmit a stable torque of 1000 N m to the steel spur gear through a

key. The diameter of the shaft connecting the gear is d = 80 mm and the width of hub is

w = 120 mm, as shown in Figure E4.1. Select a proper key to transmit the torque. If the

transmitted torque is doubled, modify the design.