Page 104 - Analytical Electrochemistry 2d Ed - Jospeh Wang

P. 104

3-6 FLOW ANALYSIS 89

rectangular channel. The ¯ow channel is formed by two plastic blocks pressing a

thin Te¯on gasket, which de®nes the very small dead volume ( 1 mL). In the wall-jet

design, the stream ¯ows from a nozzle perpendicularly onto a ¯at electrode surface

(the wall), and then spreads radially over the surface. The electrode diameter is

signi®cantly larger than that of the nozzle inlet. Since the jet remains intact up to

quite large inlet±electrode separations, it is possible to employ large-volume wall-jet

detectors that offer decreased sensitivity to the properties of the mobile phase and

simpli®ed fabrication.

It is possible to employ detectors with solutions ¯owing over a static mercury

drop electrode or a carbon-®ber microelectrode, or to use ¯ow-through electrodes,

with the electrode simply an open tube or porous matrix. The latter can offer

complete electrolysis, that is coulometric detection. The extremely small dimensions

of ultramicroelectrodes (discussed in Section 4-5.4) offer the advantages of ¯ow rate

independence (and hence a low noise level) and operation in nonconductive mobile

phases (such as those of normal-phase chromatography or supercritical ¯uid

chromatography). Ultramicroelectrodes can also greatly bene®t modern microse-

paration techniques such as open-tubular liquid chromatography or capillary zone

electrophoresis (CZE) (57). For example, cylindrical-shaped carbon or copper ®bers

can be inserted into the end of the capillary electrophoresis separation capillary (e.g.,

Figure 3-23). Such alignment of the working electrode with the end of the capillary

represents a challenge in combining electrochemistry with CZE.

CZE has recently established itself as an important separation tool due to its

impressive separation power. Since CZE separations rely on the application of strong

electric ®elds for separating the analytes, it is essential to isolate the low detection

potential from the high voltage (10±30 kV) used to affect the separation (59, 59a).

This can be accomplished by using a decoupling device (e.g., Na®on joint, porous

glass) or via end-column detection (i.e., placement of the detector opposite to the

capillary outlet in a wall-jet con®guration). The latter relies on the dramatic drop of

the potential across small capillaries (of 25 mm or less). The distance between the

detector and the capillary outlet should be as short as possible, as needed for

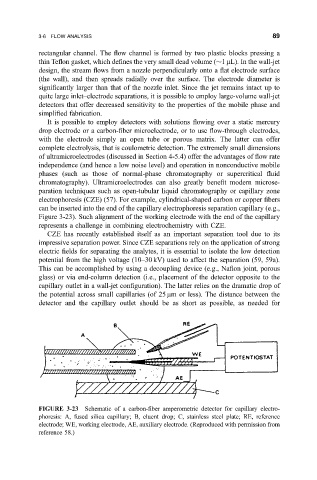

FIGURE 3-23 Schematic of a carbon-®ber amperometric detector for capillary electro-

phoresis: A, fused silica capillary; B, eluent drop; C, stainless steel plate; RE, reference

electrode; WE, working electrode, AE, auxiliary electrode. (Reproduced with permission from

reference 58.)