Page 122 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 122

66131_Ludwig_CH10C 5/30/2001 4:21 PM Page 89

Heat Transfer 89

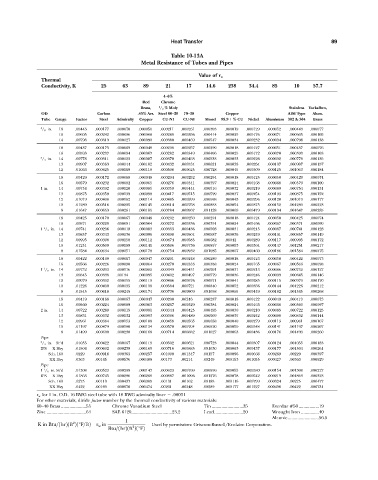

Table 10-13A

Metal Resistance of Tubes and Pipes

Value of r w

Thermal

Conductivity, K 25 63 89 21 17 14.6 238 34.4 85 10 57.7

4—6%

Red Chrome

Brass, 1 / 2 % Moly Stainless Yorkalbro,

OD Carbon .45% Ars. Steel 80—20 70—30 Copper AISI Type Alum.

Tube Gauge Factor Steel Admiralty Copper CU-NI CU-NI Monel 99.9 % CU Nickel Aluminum 302 & 304 Brass

5 / 8 in. 18 .00443 .000177 .000070 .000050 .000211 .000261 .000303 .000019 .000129 .000052 .000443 .000077

16 .00605 .000242 .000096 .000068 .000288 .000356 .000414 .000025 .000176 .000071 .000605 .000105

14 .00798 .000319 .000127 .000090 .000380 .000469 .000547 .000034 .000232 .000094 .000798 .000138

18 .00437 .000175 .000069 .000049 .000208 .000257 .000299 .000018 .000127 .000051 .000437 .000076

16 .00593 .000237 .000094 .000067 .000282 .000349 .000406 .000025 .000172 .000070 .000593 .000103

3

/ 4 in. 14 .00778 .000311 .000123 .000087 .000370 .000458 .000533 .000033 .000226 .000092 .000778 .000135

13 .00907 .000363 .000144 .000102 .000432 .000534 .000621 .000038 .000264 .000107 .000907 .000157

12 .01063 .000425 .000169 .000119 .000506 .000625 .000728 .000045 .000309 .000125 .001063 .000184

18 .00429 .000172 .000068 .000048 .000204 .000252 .000294 .000018 .000125 .000050 .000429 .000074

16 .00579 .000232 .000092 .000065 .000276 .000341 .000397 .000024 .000168 .000068 .000579 .000100

1 in. 14 .00754 .000302 .000120 .000085 .000359 .000444 .000516 .000032 .000219 .000089 .000754 .000131

13 .00875 .000350 .000139 .000098 .000417 .000515 .000599 .000037 .000254 .000103 .000875 .000152

12 .01019 .000408 .000162 .000114 .000485 .000599 .000698 .000043 .000296 .000120 .001019 .000177

10 .01289 .000516 .000205 .000145 .000614 .000758 .000883 .000054 .000375 .000152 .001289 .000223

8 .01647 .000659 .000261 .000185 .000784 .000967 .001128 .000069 .000479 .000194 .001647 .000285

18 .00425 .000170 .000067 .000048 .000202 .000250 .000291 .000018 .000124 .000050 .000425 .000074

16 .00571 .000228 .000091 .000064 .000272 .000336 .000391 .000024 .000166 .000067 .000571 .000099

1 / 4 in. 14 .00741 .000296 .000118 .000083 .000353 .000436 .000508 .000031 .000215 .000087 .000741 .000128

1

13 .00857 .000343 .000136 .000096 .000408 .000504 .000587 .000036 .000249 .000101 .000857 .000149

12 .00995 .000398 .000158 .000112 .000474 .000585 .000682 .00042 .000289 .000117 .000995 .000172

10 .01251 .000500 .000199 .000141 .000596 .000736 .000857 .000053 .000364 .000147 .001251 .000217

8 .01584 .000634 .000251 .000178 .000754 .000932 .001085 .000067 .000460 .000186 .001584 .000275

18 .00422 .000169 .000067 .000047 .000201 .000248 .000289 .000018 .000123 .000050 .000422 .000073

16 .00566 .000226 .000090 .000064 .000270 .000333 .000388 .000024 .000165 .000067 .000566 .000098

1 / 2 in. 14 .00732 .000293 .000116 .000082 .000349 .000431 .000501 .000031 .000213 .000086 .000732 .000127

1

13 .00845 .000338 .00134 .000095 .000402 .000497 .000579 .000036 .000246 .000099 .000845 .000146

12 .00979 .000392 .000155 .000110 .000466 .000576 .000671 .000041 .000285 .000115 .000979 .000170

10 .01226 .000490 .000195 .000138 .000584 .000721 .000840 .000052 .000356 .000144 .001226 .000212

8 .01545 .000618 .000245 .000174 .000736 .000909 .001058 .000065 .000449 .000182 .001545 .000268

18 .00419 .000168 .000067 .000047 .000200 .00246 .000287 .000018 .000122 .000049 .000419 .000073

16 .00560 .000224 .000089 .000063 .000267 .000329 .000384 .000024 .000163 .000066 .000560 .000097

2 in. 14 .00722 .000289 .000115 .000081 .000344 .000425 .000495 .000030 .000210 .000085 .000722 .000125

13 .00831 .000332 .000132 .000093 .000396 .000489 .000569 .000035 .000242 .000098 .000832 .000144

12 .00961 .000384 .000153 .000108 .000458 .000565 .000658 .000040 .000279 .000113 .000961 .000167

10 .01197 .000479 .000190 .000134 .000570 .000704 .000820 .000050 .000348 .000141 .001197 .000207

8 .01499 .000600 .000238 .000168 .000714 .000882 .001027 .000063 .000436 .000176 .001499 .000260

Pipe

/ 4 in. St’d .01055 .000422 .000167 .000119 .000502 .000621 .000723 .000044 .000307 .000124 .001055 .000183

3

IPS X Hvy .01504 .000602 .000239 .000169 .000716 .000885 .001030 .000063 .000437 .000177 .001504 .000261

Sch. 160 .0229 .000916 .000363 .000257 .001090 .001347 .00157 .000096 .000666 .000269 .00229 .000397

XX Hvy .0363 .00145 .000576 .000408 .00173 .00214 .00249 .000153 .001055 .000427 .00363 .000629

Pipe

1 / 2 in. St’d .01308 .000523 .000208 .000147 .000623 .000769 .000896 .000055 .000380 .000154 .001308 .000227

1

IPS X Hvy .01863 .000745 .000296 .000209 .000887 .001096 .001276 .000078 .000542 .000219 .001863 .000323

Sch. 160 .0275 .00110 .000437 .000309 .00131 .00162 .00188 .000116 .000799 .000324 .00275 .000477

XX Hvy .0422 .00169 .000670 .000474 .00201 .00248 .00289 .000177 .001227 .000496 .00422 .000731

r w for 1 in. O.D. 16 BWG steel tube with 18 BWG admiralty liner .00031

For other materials, divide factor number by the thermal conductivity of various materials:

60—40 Brass .....................55 Chrome Vanadium Steel ........ Tin ..........................35 Everdur 50.................19

Zinc .................................64 SAE 6120..................................23.2 Lead........................20 Wrought Iron ...............40

......................................... .................................................. ................................ Alcunic..........................56.5

1

2

K in Btu>1hr21ft 21°F>ft2 r w in Used by permission: Griscom-Russell/Ecolaire Corporation.

2

Btu>1hr21ft 21°F2