Page 281 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 281

66131_Ludwig_CH10G 5/30/2001 4:40 PM Page 243

Heat Transfer 243

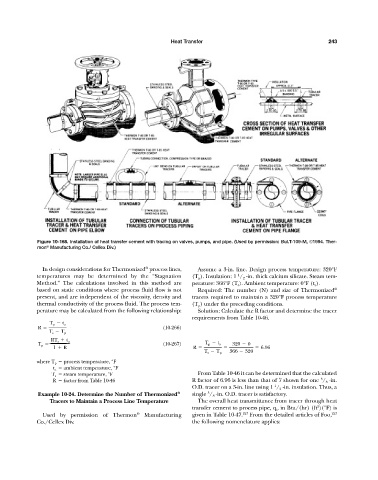

Figure 10-168. Installation of heat transfer cement with tracing on valves, pumps, and pipe. (Used by permission: Bul.T-109-M, ©1994. Ther-

®

mon Manufacturing Co./ Cellex Div.)

®

In design considerations for Thermonized process lines, Assume a 3-in. line. Design process temperature: 320°F

1

temperatures may be determined by the “Stagnation (T p ). Insulation: 1 / 2 -in. thick calcium silicate. Steam tem-

Method.” The calculations involved in this method are perature: 366°F (T s ). Ambient temperature: 0°F (t a ).

based on static conditions where process fluid flow is not Required: The number (N) and size of Thermonized ®

present, and are independent of the viscosity, density and tracers required to maintain a 320°F process temperature

thermal conductivity of the process fluid. The process tem- (T p ) under the preceding conditions.

perature may be calculated from the following relationship: Solution: Calculate the R factor and determine the tracer

requirements from Table 10-46.

T p t a

R (10-266)

T s T p

RT s t a

T p (10-267) T p t a 320 0

1 R R 6.96

T s T p 366 320

where T p process temperature, °F

t a ambient temperature, °F

T s steam temperature, °F From Table 10-46 it can be determined that the calculated

3

R factor from Table 10-46 R factor of 6.96 is less than that of 7 shown for one / 8 -in.

1

O.D. tracer on a 3-in. line using 1 / 2 -in. insulation. Thus, a

3

Example 10-24. Determine the Number of Thermonized ® single / 8 -in. O.D. tracer is satisfactory.

Tracers to Maintain a Process Line Temperature The overall heat transmittance from tracer through heat

transfer cement to process pipe, q t , in Btu/(hr) (ft )(°F) is

2

Used by permission of Thermon ® Manufacturing given in Table 10-47. 223 From the detailed articles of Foo, 223

Co./Cellex Div. the following nomenclature applies: