Page 277 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 277

66131_Ludwig_CH10G 5/30/2001 4:39 PM Page 239

Heat Transfer 239

resulting mixture can be set for the desired temperature for

direct mixing, heating jackets of vessels, and similar require-

ments, see Figures 10-163 and 10-164.

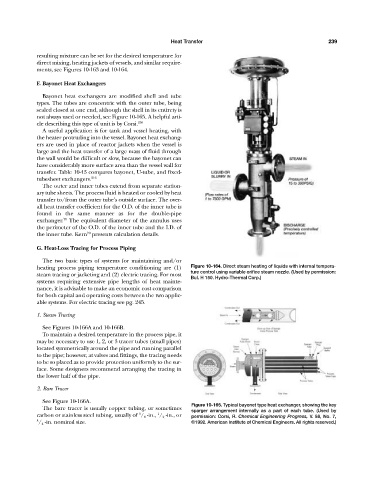

F. Bayonet Heat Exchangers

Bayonet heat exchangers are modified shell and tube

types. The tubes are concentric with the outer tube, being

sealed closed at one end, although the shell in its entirety is

not always used or needed, see Figure 10-165. A helpful arti-

cle describing this type of unit is by Corsi. 216

A useful application is for tank and vessel heating, with

the heater protruding into the vessel. Bayonet heat exchang-

ers are used in place of reactor jackets when the vessel is

large and the heat transfer of a large mass of fluid through

the wall would be difficult or slow, because the bayonet can

have considerably more surface area than the vessel wall for

transfer. Table 10-43 compares bayonet, U-tube, and fixed-

tubesheet exchangers. 216

The outer and inner tubes extend from separate station-

ary tube sheets. The process fluid is heated or cooled by heat

transfer to/from the outer tube’s outside surface. The over-

all heat transfer coefficient for the O.D. of the inner tube is

found in the same manner as for the double-pipe

70

exchanger. The equivalent diameter of the annulus uses

the perimeter of the O.D. of the inner tube and the I.D. of

70

the inner tube. Kern presents calculation details.

G. Heat-Loss Tracing for Process Piping

The two basic types of systems for maintaining and/or

heating process piping temperature conditioning are (1) Figure 10-164. Direct steam heating of liquids with internal tempera-

ture control using variable orifice steam nozzle. (Used by permission:

steam tracing or jacketing and (2) electric tracing. For most

Bul. H 150. Hydro-Thermal Corp.)

systems requiring extensive pipe lengths of heat mainte-

nance, it is advisable to make an economic cost comparison

for both capital and operating costs between the two applic-

able systems. For electric tracing see pg. 245.

1. Steam Tracing

See Figures 10-166A and 10-166B.

To maintain a desired temperature in the process pipe, it

may be necessary to use 1, 2, or 3 tracer tubes (small pipes)

located symmetrically around the pipe and running parallel

to the pipe; however, at valves and fittings, the tracing needs

to be so placed as to provide protection uniformly to the sur-

face. Some designers recommend arranging the tracing in

the lower half of the pipe.

2. Bare Tracer

See Figure 10-166A.

Figure 10-165. Typical bayonet type heat exchanger, showing the key

The bare tracer is usually copper tubing, or sometimes sparger arrangement internally as a part of each tube. (Used by

3

1

carbon or stainless steel tubing, usually of / 8 -in., / 2 -in., or permission: Corsi, R. Chemical Engineering Progress, V. 88, No. 7,

3 / 4 -in. nominal size. ©1992. American Institute of Chemical Engineers. All rights reserved.)