Page 274 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 274

66131_Ludwig_CH10G 5/30/2001 4:39 PM Page 236

236 Applied Process Design for Chemical and Petrochemical Plants

(1)

(2)

®

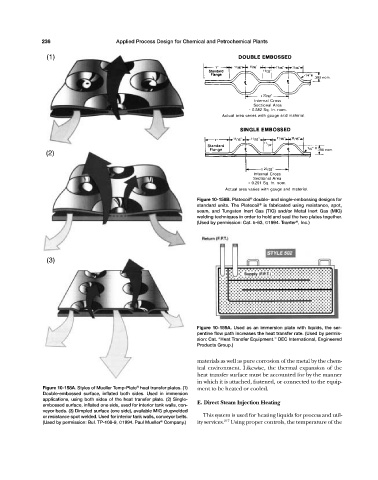

Figure 10-158B. Platecoil double- and single-embossing designs for

standard units. The Platecoil is fabricated using resistance, spot,

®

seam, and Tungsten Inert Gas (TIG) and/or Metal Inert Gas (MIG)

welding techniques in order to hold and seal the two plates together.

(Used by permission: Cat. 5-63, ©1994. Tranter , Inc.)

®

(3)

Figure 10-159A. Used as an immersion plate with liquids, the ser-

pentine flow path increases the heat transfer rate. (Used by permis-

sion: Cat. “Heat Transfer Equipment.” DEC International, Engineered

Products Group.)

materials as well as pure corrosion of the metal by the chem-

ical environment. Likewise, the thermal expansion of the

heat transfer surface must be accounted for by the manner

in which it is attached, fastened, or connected to the equip-

Figure 10-158A. Styles of Mueller Temp-Plate heat transfer plates. (1) ment to be heated or cooled.

®

Double-embossed surface, inflated both sides. Used in immersion

applications, using both sides of the heat transfer plate. (2) Single-

embossed surface, inflated one side, used for interior tank walls, con- E. Direct Steam Injection Heating

veyor beds. (3) Dimpled surface (one side), available MIG plugwelded

or resistance spot welded. Used for interior tank walls, conveyor belts. This system is used for heating liquids for process and util-

®

(Used by permission: Bul. TP-108-9, ©1994. Paul Mueller Company.) ity services. 217 Using proper controls, the temperature of the