Page 35 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 35

66131_Ludwig_CH10A 5/30/2001 4:07 PM Page 25

Heat Transfer 25

those in the shell are adjusted by design to provide the nec-

essary arrangements for maintenance of proper heat trans-

fer fluid velocities and film conditions. Consider the two

classes of baffles described in the following sections.

A. Tube Side Baffles

These baffles are built into the head and return ends of

an exchanger to direct the fluid through the tubes at the

proper relative position in the bundle for good heat transfer

as well as for fixing velocity in the tubes, see Figures 10-1D

and 10-3.

Baffles in the head and return ends of exchangers are

either welded or cast in place. The arrangement may take

any of several reasonable designs, depending upon the

number of tube-side passes required in the performance of

the unit. The number of tubes per pass is usually arranged

about equal. However, depending upon the physical

changes in the fluid volume as it passes through the unit, the

number of tubes may be significantly different in some of

the passes. Practical construction limits the number of tube-

side passes to 8—10, although a larger number of passes may

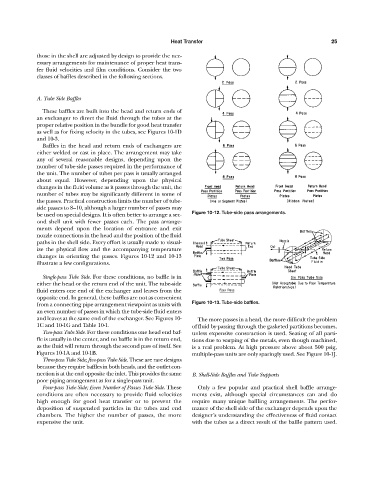

be used on special designs. It is often better to arrange a sec- Figure 10-12. Tube-side pass arrangements.

ond shell unit with fewer passes each. The pass arrange-

ments depend upon the location of entrance and exit

nozzle connections in the head and the position of the fluid

paths in the shell side. Every effort is usually made to visual-

ize the physical flow and the accompanying temperature

changes in orienting the passes. Figures 10-12 and 10-13

illustrate a few configurations.

Single-pass Tube Side. For these conditions, no baffle is in

either the head or the return end of the unit. The tube-side

fluid enters one end of the exchanger and leaves from the

opposite end. In general, these baffles are not as convenient

from a connecting pipe arrangement viewpoint as units with Figure 10-13. Tube-side baffles.

an even number of passes in which the tube-side fluid enters

and leaves at the same end of the exchanger. See Figures 10- The more passes in a head, the more difficult the problem

1C and 10-1G and Table 10-1. of fluid by-passing through the gasketed partitions becomes,

Two-pass Tube Side. For these conditions one head end baf- unless expensive construction is used. Seating of all parti-

fle is usually in the center, and no baffle is in the return end, tions due to warping of the metals, even though machined,

as the fluid will return through the second pass of itself. See is a real problem. At high pressure above about 500 psig,

Figures 10-1A and 10-1B. multiple-pass units are only sparingly used. See Figure 10-1J.

Three-pass Tube Side; five-pass Tube Side. These are rare designs

because they require baffles in both heads, and the outlet con-

nection is at the end opposite the inlet. This provides the same B. Shell-Side Baffles and Tube Supports

poor piping arrangement as for a single-pass unit.

Four-pass Tube Side; Even Number of Passes Tube Side. These Only a few popular and practical shell baffle arrange-

conditions are often necessary to provide fluid velocities ments exist, although special circumstances can and do

high enough for good heat transfer or to prevent the require many unique baffling arrangements. The perfor-

deposition of suspended particles in the tubes and end mance of the shell side of the exchanger depends upon the

chambers. The higher the number of passes, the more designer’s understanding the effectiveness of fluid contact

expensive the unit. with the tubes as a direct result of the baffle pattern used.