Page 143 - Applied Petroleum Geomechanics

P. 143

136 Applied Petroleum Geomechanics

size. Griffith (1921) found that this seemed contrary to the well-known fact

that larger cracks are propagated more easily than smaller ones. This

anomaly led Griffith to a theoretical analysis of fractures based on the point

of view of minimum potential energy (Fischer-Cripps, 2007). Griffith

proposed that the reduction in strain energy due to the formation of a crack

must be equal to or greater than the increase in surface energy required by

the new crack faces. According to Griffith, there are two conditions

necessary for crack growth:

(1) The bonds at the crack tip must be stressed to the point of failure. The

stress at the crack tip is a function of the stress concentration factor,

which is dependent on the ratio of its radius of curvature to its length.

(2) For an increment of crack extension, the amount of strain energy

released must be greater than or equal to that required for the surface

energy of the two new crack faces.

Based on the fact that tensile strength of an actual material is much

lower than that theoretically predicted, Griffith (1921) postulated that

typical brittle materials inevitably contain numerous submicroscopic flaws,

microcracks, or other discontinuities of heterogeneity, which are distributed

with random orientation throughout the volume of the material (Whittaker

et al., 1992). These cracks serve as stress concentrators, and fracture initi-

ation is caused by the stress concentrations at the tips of these minute

internal cracks. These cracks have since been referred to as the Griffith flaws

or the Griffith cracks.

The fundamental concept of the Griffith theory is that the bounding

surfaces of a solid possess a surface tension, just as those of a liquid do, and

when a crack spreads the decrease in the strain energy is balanced by an

increase in the potential energy due to this surface tension (Sneddon, 1946).

The calculation of the effect of the presence of a crack on the energy of

an elastic body is based on Inglis’s solution (Inglis, 1913) of the two-

dimensional equations of elastic equilibrium in the space bounded by

two concentric ellipses, the crack being then taken to be an ellipse of zero

eccentricity. Denoting the surface tension of the material of the solid body

by T, the length of the crack by 2a, and Young’s modulus of the material of

the body by E, Griffith showed that, in the case of plane stress, the crack

will spread when the tensile stress P, applied normally to the direction of

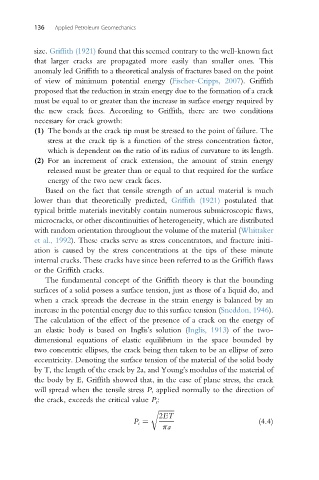

the crack, exceeds the critical value P c :

2ET

r ffiffiffiffiffiffiffiffiffi

P c ¼ (4.4)

pa