Page 32 - Applied statistics and probability for engineers

P. 32

10 Chapter 1/The Role of Statistics in Engineering

16

14

12

10

y

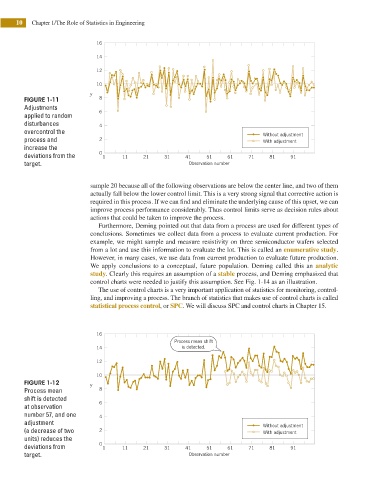

FIGURE 1-11 8

Adjustments

6

applied to random

disturbances 4

overcontrol the Without adjustment

process and 2 With adjustment

increase the

0

deviations from the 1 11 21 31 41 51 61 71 81 91

target. Observation number

sample 20 because all of the following observations are below the center line, and two of them

actually fall below the lower control limit. This is a very strong signal that corrective action is

required in this process. If we can ind and eliminate the underlying cause of this upset, we can

improve process performance considerably. Thus control limits serve as decision rules about

actions that could be taken to improve the process.

Furthermore, Deming pointed out that data from a process are used for different types of

conclusions. Sometimes we collect data from a process to evaluate current production. For

example, we might sample and measure resistivity on three semiconductor wafers selected

from a lot and use this information to evaluate the lot. This is called an enumerative study.

However, in many cases, we use data from current production to evaluate future production.

We apply conclusions to a conceptual, future population. Deming called this an analytic

study. Clearly this requires an assumption of a stable process, and Deming emphasized that

control charts were needed to justify this assumption. See Fig. 1-14 as an illustration.

The use of control charts is a very important application of statistics for monitoring, control-

ling, and improving a process. The branch of statistics that makes use of control charts is called

statistical process control, or SPC. We will discuss SPC and control charts in Chapter 15.

16

Process mean shift

14 is detected.

12

10

FIGURE 1-12 y

Process mean 8

shift is detected 6

at observation

number 57, and one 4

adjustment Without adjustment

(a decrease of two 2 With adjustment

units) reduces the

deviations from 0 1 11 21 31 41 51 61 71 81 91

target. Observation number