Page 35 - Applied statistics and probability for engineers

P. 35

Section 1-4/Probability and Probability Models 13

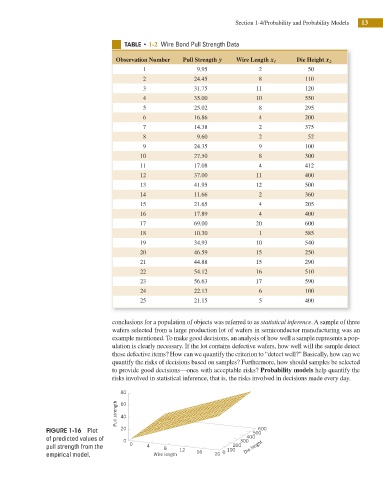

5"#-& t 1-2 Wire Bond Pull Strength Data

Observation Number Pull Strength y Wire Length x 1 Die Height x 2

1 9.95 2 50

2 24.45 8 110

3 31.75 11 120

4 35.00 10 550

5 25.02 8 295

6 16.86 4 200

7 14.38 2 375

8 9.60 2 52

9 24.35 9 100

10 27.50 8 300

11 17.08 4 412

12 37.00 11 400

13 41.95 12 500

14 11.66 2 360

15 21.65 4 205

16 17.89 4 400

17 69.00 20 600

18 10.30 1 585

19 34.93 10 540

20 46.59 15 250

21 44.88 15 290

22 54.12 16 510

23 56.63 17 590

24 22.13 6 100

25 21.15 5 400

conclusions for a population of objects was referred to as statistical inference. A sample of three

wafers selected from a large production lot of wafers in semiconductor manufacturing was an

example mentioned. To make good decisions, an analysis of how well a sample represents a pop-

ulation is clearly necessary. If the lot contains defective wafers, how well will the sample detect

these defective items? How can we quantify the criterion to “detect well?” Basically, how can we

quantify the risks of decisions based on samples? Furthermore, how should samples be selected

to provide good decisions—ones with acceptable risks? Probability models help quantify the

risks involved in statistical inference, that is, the risks involved in decisions made every day.

80

Pull strength 60

40

600

FIGURE 1-16 Plot 20 500

of predicted values of 0 300 400

pull strength from the 0 4 8 12 100 200 Die height

empirical model. Wire length 16 20 0