Page 285 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 285

CHAP TER 1 0. 1 Tyres and wheels

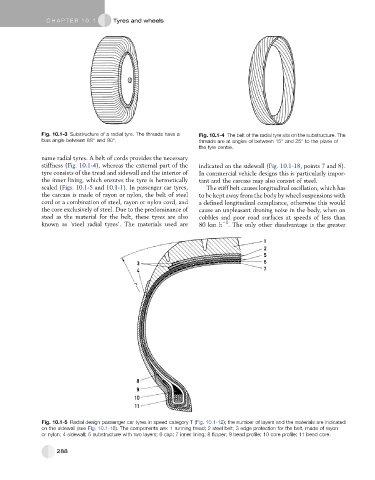

Fig. 10.1-3 Substructure of a radial tyre. The threads have a Fig. 10.1-4 The belt of the radial tyre sits on the substructure. The

bias angle between 88 and 90 . threads are at angles of between 15 and 25 to the plane of

the tyre centre.

name radial tyres. A belt of cords provides the necessary

stiffness (Fig. 10.1-4), whereas the external part of the indicated on the sidewall (Fig. 10.1-18, points 7 and 8).

tyre consists of the tread and sidewall and the interior of In commercial vehicle designs this is particularly impor-

the inner lining, which ensures the tyre is hermetically tant and the carcass may also consist of steel.

sealed (Figs. 10.1-5 and 10.1-1). In passenger car tyres, The stiff belt causes longitudinal oscillation, which has

the carcass is made of rayon or nylon, the belt of steel to be kept away from the body by wheel suspensions with

cord or a combination of steel, rayon or nylon cord, and a defined longitudinal compliance, otherwise this would

the core exclusively of steel. Due to the predominance of cause an unpleasant droning noise in the body, when on

steel as the material for the belt, these tyres are also cobbles and poor road surfaces at speeds of less than

1

known as ‘steel radial tyres’. The materials used are 80 km h . The only other disadvantage is the greater

Fig. 10.1-5 Radial design passenger car tyres in speed category T (Fig. 10.1-12); the number of layers and the materials are indicated

on the sidewall (see Fig. 10.1-18). The components are: 1 running tread; 2 steel belt; 3 edge protection for the belt, made of rayon

or nylon; 4 sidewall; 5 substructure with two layers; 6 cap; 7 inner lining; 8 flipper; 9 bead profile; 10 core profile; 11 bead core.

288