Page 34 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 34

CH AP TER 2 .1 Measurement of torque, power, speed and fuel consumption

clearance, between water-cooled steel loss plates. A mag- Although no longer so widely used, an alternative form of

netic field parallel to the machine axis is generated by two eddy-current machine is also available. This employs

annular coils and motion ofthe rotorgivesrise to changesin a simple disc or drum design of rotor in which eddy

the distribution of magnetic flux in the loss plates. This in currents are induced and the heat developed is trans-

turn gives rise to circulating eddy currents and the dissi- ferred to water circulated through the gaps between

pation of power in the form of electrical resistive losses. rotor and stator. These ‘wet gap’ machines are liable to

Energy is transferred in the form of heat to cooling water corrosion if left static for any length of time, have higher

circulating through passages in the loss plates, while some inertia, and have a high level of minimum torque, arising

cooling is achieved by the radial flow of air in the gaps be- from drag of the cooling water in the gap.

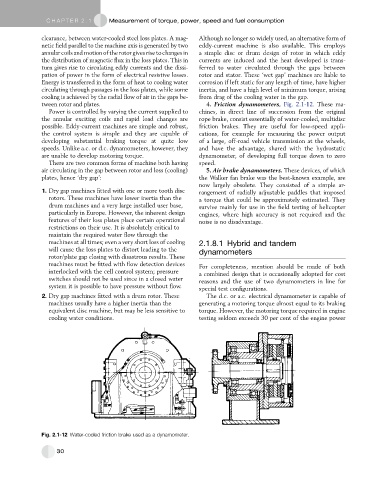

tween rotor and plates. 4. Friction dynamometers, Fig. 2.1-12. These ma-

Power is controlled by varying the current supplied to chines, in direct line of succession from the original

the annular exciting coils and rapid load changes are rope brake, consist essentially of water-cooled, multidisc

possible. Eddy-current machines are simple and robust, friction brakes. They are useful for low-speed appli-

the control system is simple and they are capable of cations, for example for measuring the power output

developing substantial braking torque at quite low of a large, off-road vehicle transmission at the wheels,

speeds. Unlike a.c. or d.c. dynamometers, however, they and have the advantage, shared with the hydrostatic

are unable to develop motoring torque. dynamometer, of developing full torque down to zero

There are two common forms of machine both having speed.

air circulating in the gap between rotor and loss (cooling) 5. Air brake dynamometers. These devices, of which

plates, hence ‘dry gap’: the Walker fan brake was the best-known example, are

now largely obsolete. They consisted of a simple ar-

1. Dry gap machines fitted with one or more tooth disc rangement of radially adjustable paddles that imposed

rotors. These machines have lower inertia than the a torque that could be approximately estimated. They

drum machines and a very large installed user base, survive mainly for use in the field testing of helicopter

particularly in Europe. However, the inherent design engines, where high accuracy is not required and the

features of their loss plates place certain operational noise is no disadvantage.

restrictions on their use. It is absolutely critical to

maintain the required water flow through the

machines at all times; even a very short loss of cooling 2.1.8.1 Hybrid and tandem

will cause the loss plates to distort leading to the dynamometers

rotor/plate gap closing with disastrous results. These

machines must be fitted with flow detection devices For completeness, mention should be made of both

interlocked with the cell control system; pressure a combined design that is occasionally adopted for cost

switches should not be used since in a closed water reasons and the use of two dynamometers in line for

system it is possible to have pressure without flow.

special test configurations.

2. Dry gap machines fitted with a drum rotor. These The d.c. or a.c. electrical dynamometer is capable of

machines usually have a higher inertia than the generating a motoring torque almost equal to its braking

equivalent disc machine, but may be less sensitive to torque. However, the motoring torque required in engine

cooling water conditions. testing seldom exceeds 30 per cent of the engine power

Fig. 2.1-12 Water-cooled friction brake used as a dynamometer.

30