Page 640 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 640

CHAP TER 1 8. 2 Materials for consideration and use in automotive body structures

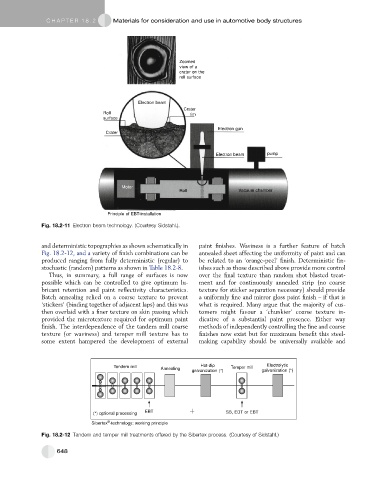

Zoomed

view of a

crater on the

roll surface

Electron beam

Crater

Roll rim

surface

Electron gun

Crater

Electron beam pump

Motor

Roll Vacuum chamber

Principle of EBT-installation

Fig. 18.2-11 Electron beam technology. (Courtesy Sidstahl.).

and deterministic topographies as shown schematically in paint finishes. Waviness is a further feature of batch

Fig. 18.2-12, and a variety of finish combinations can be annealed sheet affecting the uniformity of paint and can

produced ranging from fully deterministic (regular) to be related to an ‘orange-peel’ finish. Deterministic fin-

stochastic (random) patterns as shown in Table 18.2-8. ishes such as those described above provide more control

Thus, in summary, a full range of surfaces is now over the final texture than random shot blasted treat-

possible which can be controlled to give optimum lu- ment and for continuously annealed strip (no coarse

bricant retention and paint reflectivity characteristics. texture for sticker separation necessary) should provide

Batch annealing relied on a coarse texture to prevent a uniformly fine and mirror gloss paint finish – if that is

‘stickers’ (binding together of adjacent laps) and this was what is required. Many argue that the majority of cus-

then overlaid with a finer texture on skin passing which tomers might favour a ‘chunkier’ coarse texture in-

provided the microtexture required for optimum paint dicative of a substantial paint presence. Either way

finish. The interdependence of the tandem mill coarse methods of independently controlling the fine and coarse

texture (or waviness) and temper mill texture has to finishes now exist but for maximum benefit this steel-

some extent hampered the development of external making capability should be universally available and

Tandem mill Hot-dip Temper mill Electrolytic

Annealing

galvanization (*) galvanization (*)

EBT SB, EDT or EBT

(*) optional processing

©

Sibertex -technology: working principle

Fig. 18.2-12 Tandem and temper mill treatments offered by the Sibertex process. (Courtesy of Sidstahl.)

648