Page 239 - Battery Reference Book

P. 239

Nickel-cadmium secondary batteries 19/5

I Microporous separator I 0

I t -

I

I

I- Avaiiable-' I I , ,

I I capacity i 1 i k i i 0, production

li ! Charqing

..

reserve

$ i p =constant

t --------

a t

I

>

1

Normal ' Overcharge lu

charge

t-

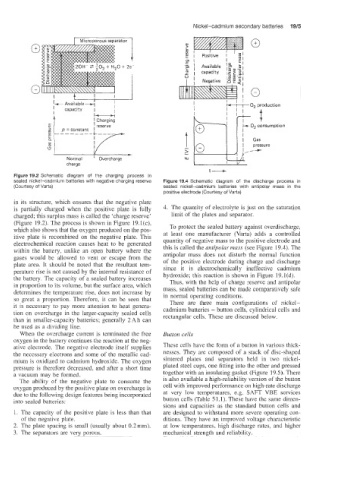

Figure 19.2 Schematic diagram of the charging process in

sealed nickel-cadmium batteries with negative charging reserve Figure 19.4 Schematic diagram of the discharge process in

(Courtesy of Varta) sealed nickel-cadmium batteries with antipolar mass in the

positive electrode (Courtesy of Varta)

in its structure, which ensures that the negative plate

is partially charged when the positive plate is fully 4. The quantity of electrolyte is just on the saturation

charged; this surplus mass is called the 'charge reserve' limit of the plates and separator.

(Figure 19.2). The process is shown in Figure 19.1(c),

which also shows that the oxygen produced on the pos- To protect the sealed battery against overdischarge,

itive plate is recombined on the negative plate. This at least one manufacturer (Varta) adds a controlled

electrochemical reaction causes heat to be generated quantity of negative mass to the positive electrode and

this is called the antipolar mass (see Figure 19.4). The

within the battery, unlike an open battery where the

gases would be allowed to vent or escape from the antipolar mass does not disturb the normal function

plate area. It should be noted that the resultant tem- of the positive electrode during charge and discharge

since it is electrochemically ineffective cadmium

perature rise is not caused by the internal resistance of hydroxide; this reaction is shown in Figure 19.1(d).

the battery. Tne capacity of a sealed battery increases Thus, with the help of charge reserve and antipolar

in proportion to its volume, but the surface area, which

determines the temperature rise, does not increase by mass, sealed batteries can be made comparatively safe

so great a proportion. Therefore, it can be seen that in normal operating conditions.

There are three main configurations of nickel-

it is necessary to pay more attention to heat genera- cadmium batteries - button cells. cylindrical cells and

tion on overchaLrge in the larger-capacity sealed cells rectangular cells. These are discussed below.

than in smaller-capacity batteries; generally 2 Ah can

be used as a dividing line.

When the ov'ercharge current is terminated the free Button cells

oxygen in the battery continues the reaction at the neg-

ative electrode. The negative electrode itself supplies These cells have the form of a button in various thick-

the necessary electrons and some of the metaIlic cad- nesses. They are composed of a stack of disc-shaped

mium is oxidized to cadmium hydroxide. The oxygen sintered plates and separators held in two nickel-

pressure is then-fore decreased, and after a short time plated steel cups, one fitting into the other and pressed

a vacuum may be formed. together with an insulating gasket (Figure 19.5). There

The ability of the negative plate to consume the is also available a high-reliability version of the button

oxygen produced by the positive plate on overcharge is cell with improved performance on high-rate discharge

due to the following design features being incorporated at very low temperatures, e.g. SAFT VBE services

into sealed batteries: button cells (Table 51.1). These have the same dimen-

sions and capacities as the standard button cells and

I. The capacity of the positive plate is less than that are designed to withstand more severe operating con-

of the negative plate. ditions. They have an improved voltage characteristic

2. The plate spacing is small (usually about 0.2mm). at low temperatures, high discharge rates, and higher

3. The separators are very porous. mechanical strength and reliability.