Page 241 - Battery Reference Book

P. 241

Nickel-cadmium secondary batteries 19/7

Most of the Eveready high-rate cylindrical cells have These cells are based on the following reactions:

a resealing pressure vent; the others have a puncture-

type failsafe venting mechanism. The resealing pres- Negative electrode: Cd2+ + 20H- + Cd(OH), (19.3)

sure vent is shown, for the 'Sub C' cell, in Figure 19.7; Positive electrode: Ni2+ + 20H- + Ni(0H)z (19.4)

this vent permits the cell to release excess gas evolved

if the cell is abused, for example. When the internal The design comprises positive and negative electrodes

pressure has dropped to an acceptable level, the vent and the separator being wound together to form a spiral

will reseal, permitting the cell to be recycled in the nor- which is inserted in a cylindrical can. The separator

mal manner wiih little or no further loss of electrolyte consists of polyamide or polypropylene non-woven

or capacity. felt. The negative electrode is connected to the cell

Manufacturers usually provide a complete specifi- cover which contains a resealing safety vent. The cover

cation for each of their range of batteries. A sample is insulated from the can by a plastic gasket which

specification for a battery in the Union Carbide range also acts as a gas-tight seal. Cell closure is achieved

is shown in Table 19.1 and Figure 19.8. by crimping the top edge of the can over the gasket.

Recent years have seen distinct improvements in Cylindrical cells rely on gas recombination to main-

capacity of sealed nickel-cadmium cylindrical cells. tain internal pressure below the relief pressure of the

safety vent during charging. The cell therefore has

Thus, the AA size cell has improved in capacity from an excess of negative capacity ensuring that the pos-

0.45Ah in 1970 to 0.8Ah in 1990. itive electrode always becomes fully charged before

the negative electrode.

Oxygen is generated at the positive electrode and

passes through the separator where it reacts with the

negative electrode

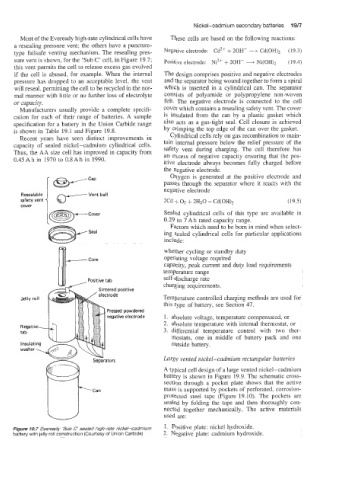

Resealable Vent ball

2Cd + 02 + 2H20 - Cd(OH)2 (19.5)

cover

Cover Sealed cylindrical cells of this type are available in

0.29 to 7 Ah rated capacity range.

Factors which need to be born in mind when select-

ing sealed cylindrical cells for particular applications

include:

whether cycling or standby duty

operating voltage required

capacity, peak current and duty load requirements

temperature range

self-discharge rate

charging requirements.

Jelly roll Temperature controlled charging methods are used for

this type of battery, see Section 47.

Pressed powdered

negative electrode 1. absolute voltage, temperature compensated, or

2. absolute temperature with internal thermostat, or

Negative-

tab 3. differential temperature control with two ther-

mostats, one in middle of battery pack and one

washer -. outside battery.

insulating

Large vented nickel-cadmium rectangular batteries

A typical cell design of a large vented nickel-cadmium

battery is shown in Figure 19.9. The schematic cross-

section through a pocket plate shows that the active

mass is supported by pockets of perforated, corrosion-

protected steel tape (Figure 19.10). The pockets are

sealed by folding the tape and then thoroughly con-

nected together mechanically. The active materials

used are:

1. Positive plate: nickel hydroxide.

Figure 19.7 Eveready 'Sub C' sealed high-rate nickel-cadmium

battery with jelly roll construction (Courtesy of Union Carbide) 2. Negative plate: cadmium hydroxide.