Page 283 - Battery Reference Book

P. 283

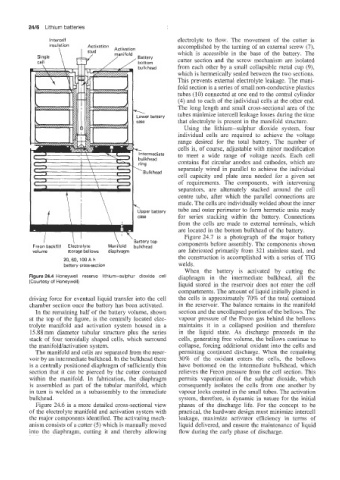

24/6 Lithium batteries

Intercell electrolyte to flow. The movement of the cutter is

insulation Activation accomplished by the turning of an external screw (7),

Activation

manifold which is accessible in the base of the battery. The

Single / , Batterv

cutter section and the screw mechanism are isolated

from each other by a small collapsible metal cup (9),

which is hermetically sealed between the two sections.

This prevents external electrolyte leakage. The mani-

fold section is a series of small non-conductive plastics

tubes (10) connected at one end to the central cylinder

(4) and to each of the individual cells at the other end.

The long length and small cross-sectional area of the

tubes minimize intercell leakage losses during the time

that electrolyte is present in the manifold structure.

Using the lithium-sulphur dioxide system, four

individual cells are required to achieve the voltage

range desired for the total battery. The number of

cells is, of course, adjustable with minor modification

to meet a wide range of voltage needs. Each cell

contains flat circular anodes and cathodes, which are

separately wired in parallel to achieve the individual

cell capacity and plate area needed for a given set

of requirements. The components, with intervening

separators, are alternately stacked around the cell

centre tube, after which the parallel connections are

made. The cells are individually welded about the inner

tube and outer perimeter to form hermetic units ready

for series stacking within the battery. Connections

from the cells are made to external terminals, which

are located in the bottom bulkhead of the battery.

\' \ ' top Figure 24.7 is a photograph of the major battery

'

Battery

Freon backfil I Electrolyte Manifold bulkhead components before assembly. The components shown

volume storage bellows diaphragm are fabricated primarily from 321 stainless steel, and

the construction is accomplished with a series of TIG

20,60, 100 A h

battery cross-section welds.

When the battery is activated by cutting the

Figure 24.4 Honeywell reserve lithium-sulphur dioxide cell diaphragm in the intermediate bulkhead, all the

(Courtesy of Honeywell)

liquid stored in the reservoir does not enter the cell

compartments. The amount of liquid initially placed in

driving force for eventual liquid transfer into the cell the cells is approximately 70% of the total contained

chamber section once the battery has been activated. in the reservoir. The balance remains in the manifold

In the remaining half of the battery volume, shown section and the uncollapsed portion of the bellows. The

at the top of the figure, is the centrally located elec- vapour pressure of the Freon gas behind the bellows

trolyte manifold and activation system housed in a maintains it in a collapsed position and therefore

15.88 mm diameter tubular structure plus the series in the liquid state. As discharge proceeds in the

stack of four toroidally shaped cells, which surround cells, generating free volume, the bellows continue to

the manifoldactivation system. collapse, forcing additional oxidant into the cells and

The manifold and cells are separated from the reser- permitting continued discharge. When the remaining

voir by an intermediate bulkhead. In the bulkhead there 30% of the oxidant enters the cells, the bellows

is a centrally positioned diaphragm of sufficiently thin have bottomed on the intermediate bulkhead, which

section that it can be pierced by the cutter contained relieves the Freon pressure from the cell section. This

within the manifold. In fabrication, the diaphragm permits vaporization of the sulphur dioxide, which

is assembled as part of the tubular manifold, which consequently isolates the cells from one another by

in turn is welded as a subassembly to the immediate vapour locks created in the small tubes. The activation

bulkhead. system, therefore, is dynamic in nature for the initial

Figure 24.6 is a more detailed cross-sectional view phases of the discharge life. For the concept to be

of the electrolyte manifold and activation system with practical. the hardware design must minimize intercell

the major components identified. The activating mech- leakage, maximize activator efficiency in terms of

anism consists of a cutter (5) which is manually moved liquid delivered, and ensure the maintenance of liquid

into the diaphragm, cutting it and thereby allowing flow during the early phase of discharge.