Page 288 - Battery Reference Book

P. 288

Lithium solid electrolyte primary batteries 2416 1

Cover These batteries currently under development hold

EB Weld assembly the promise of spill-proof, rugged batteries with long

shelf lives, with high energy density and virtually

unlimited geometrical possibilities. They are based on

a range of materials known as fast ion conductors

such as beta alumina which are capable of conducting

Insulator (cover)

alkali metal ions such as lithium to levels greater than

s

RS Weld 10-~ cm-'.

In solid polymer electrolyte-composite cathode

Top spacer types, solid polymer electrolytes, a more recently

developed material, have this required conductivity

and are seen as ideal electrolytes for solid state

Spacer batteries.

A recent solid state battery design, lithium compos-

ite cathode batteries, developed at Harwell, features

Anode a lithium ion conducting polymer electrolyte (e.g.,

SeDarator ~ assembly

assembly polyethylene oxide) and a solid intercalation cathode.

The battery is made up of a sandwich of lithiurn foil

(50 pm), polymer-electrolyte (50 pm)3 composite cath-

ode (various types have been studied including 'V6Q13,

Cathodeand --i

case assembly Tis2, MoO2, etc., plus 5% carbon black) (56pm) and

a nickel foil current collector (10 pm). Thus total cell

thickness is 150-200pm and areas can range from

cm2 to m2.

In a typical V601s-based cell design a cell area is

40cm2 and this gives a capacity of 80m Ah. The

(a) G2679 energy density is about 200W h/kg-'. This cell, when

discharged at 120°C from 2.8V to 1.7V at the C/1@

rate yielded 100% of its theoretical capacity. More than

TlG Weld 50% of theoretical cell capacity was available when

Ball seal Anode discharge was carried out at the C rate, 80% at the C/2

assem bl y rate and 100% at the C/4 rate or less. A disadvantage

! I of this type of cell is capacity decline during cycling.

14, Thus after 300 cycles capacity had decreased to about

60% of theoretical capacity. Attention to charging

Electrolyte

detail may overcome this limitation.

Current work is concerned with the development

of cells which operate at room temperature as these

are seen to have applications in the small. portable

equipment market.

(b) G3025

The Hawell development lithium-V205 solid state

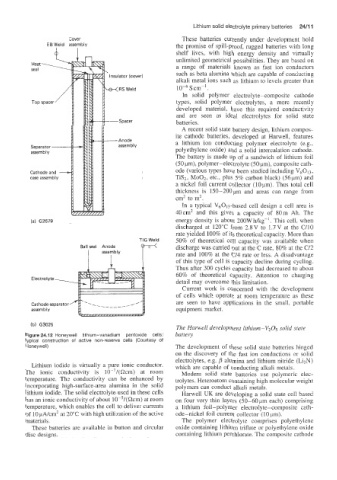

Figure 24.12 Honeywell lithium-vanadium pentoxide cells: battery

typical construction of active non-reserve cells (Courtesy of

Honeywell) The development of these solid state batteries hinged

on the discovery of the fast ion conductions or solid

electrolytes, e.g. /3 alumina and lithium nitride (Li3N)

Lithium iodidle is virtually a pure ionic conductor. which are capable of conducting alkali metals.

The ionic con(ductivity is l@-'/(Qcm) at room Modern solid state batteries ose poiymeric elec-

temperature. Thle conductivity can be enhanced by trolytes. Heteroatom containing high molecular weight

incorporating high-surface-area alumina in the solid polymers can conduct alkali metals.

lithium iodide. The solid electrolyte used in these cells Hanvell UK are developing a solid state cell based

has an ionic conductivity of about 10-5/(Q~m) at room on four very thin layers (50-60pm each) comprising

temperature, which enables the cell to deliver currents a lithium foil-polymer electrolyte-composite cath-

of 10 pA/sm2 at XYC with high utilization of the active ode-nickel foil current sollector (10 pm).

materials. The polymer electrolyte comprises polyethylene

These batteries are available in button and circular oxide containing lithium triflate or polyethylene oxide

disc designs. containing lithium perchlorate. The composite czhode