Page 290 - Battery Reference Book

P. 290

Lithium-manganese dioxide primary batteries 24/13

iodine reduced fiorming additional lithium iodide. At sharpness of this ‘knee’ is a worst case approximation.

the anode: Under a 90 kQ load, at least 5 months should elapse

as cell impedance increases from 15 to 40kQ.

=

2~i 2~i+ + 2e- (24.11)

The open circuit voltage of the cell is 2.8 V and the

At the cathode (11 = 6): overall energy density is typically 150-25OmW h/g.

As the cell is discharged, lithium ions are transported

2Li’ + 2e- + P2VPnIz = P2VP (n-1) 12 + LiI (24.12) through the electrolyte to the cathode where iodide ions

are being formed. Thus, as the discharge continues, the

Net reaction: thickness of the electrolyte increases, until ultimately

2Li + P2VPnI2 = P2VP (n- 1) 12 + 2LiI (24.13) its impedance becomes the current limiting factor.

Two main types of medical pacemaker lithium-

The lithium iodide, which serves as both electrolyte iodine cells are manufactured:

and separator, aizcumulates as the cell is discharged

increasing the internal resistance. The result is an Type 1 Ribbed lithium anode to maximize anode area

and minimize impedance.

initial linear decline in voltage as can be seen in Type 2 Pelletized cathode to reduce cell impedance

Figure 24.15. Later, when the P2VP loses most of its and reduce migration of cathode material to

iodine, the cathode itself begins to rise in resistance.

This results in the ‘knee’ seen in the voltage-time the anode.

curves of pacemaker cells shown in Figure 24.15. The

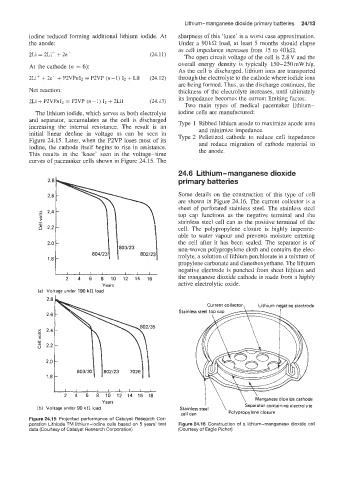

24.6 Lithium-manganese dioxide

primary batteries

Some details on the construction of this type of cell

are shown in Figure 24.16. The current collector is a

sheet of perforated stainless steel. The stainless steel

top cap functions as the negative terminal and the

stainless steel cell can as the positive terminal of the

cell. The polypropylene closure is highly imperme-

able to water vapour and prevents moisture entering

the cell after it has been sealed. The separator is of

non-woven polypropylene cloth and contains the elec-

trolyte, a solution of lithium perchlorate in a mixture of

propylene carbonate and dimethoxyethane. The lithium

negative electrode is punched from sheet lithium and

2 4 6 8 10 12 14 16 the manganese dioxide cathode is made from a highly

Years active electrolytic oxide.

(a) Voltage under 190 kR load

Current collector, Lithium negative electrode

2 4 6 8 10 12 14 16 18 \

I \

Years Manganese dioxide cathode

(b) Voltage under 90 kR load Stainless steel Separator containing electrolyte

cell can Polypropylene closure

Figure 24.15 Projescted performance of Catalyst Research Cor-

poration Lithiode TIM lithium-iodine cells based on 5 years’ test Figure 24.16 Construction of a lithium-manganese dioxide cell

data (Courtesy of Catalyst Research Corporation) (Courtesy of Eagle Picher)