Page 289 - Battery Reference Book

P. 289

24/12 Lithium batteries

is based on vanadium pentoxide (e.g. 45% VZQj, 5% problems associated with conventional batteries, such

carbon black, 50% polyethylene oxide, PEQ4). as leakage, self-discharge and separator failure, and so

produce a power source of exceptional reliability.

The Duracell lithium-titanium disulphide secondary A typical cell is constructed by placing in contact a

solid state battery lithium anode and an electronically conducting charge-

transfer complex of iodine and poly-2-vinylpyridine

This battery produced by P.R. Mallory (now Duracell) (P2VP) containing an excess of iodine. A thin layer of

operates at 300°C and uses a lithium-silicon alloy in lithium iodide is immediately formed, which becomes

cell construction, as lithium melts below its operating the electrolyte of the cell and prevents any further

temperature. The cell has a voltage of 2.4V at 300°C direct reaction between the active cell components.

and a practical energy density of 280Wh/kg-'. The Catalyst Research Corporation (USA) is a major

basic cell reaction is: manufacturer of lithium-iodine batteries used for

pacemaker and other applications. The Catalyst

Li,Si(s) + x TiS2(s) + Li,-lSi(s) + Li(TiSz),(s) (24.10)

Research Series 800 cells use the 'lithium envelope'

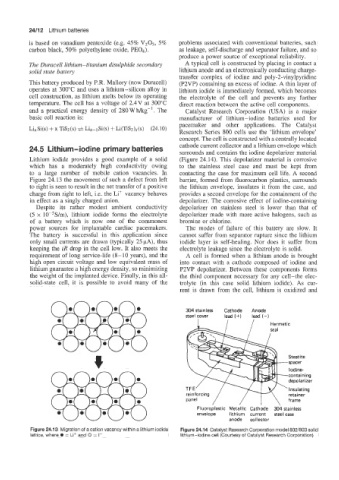

concept. The cell is constructed with a centrally located

cathode current collector and a lithium envelope which

24.5 Lithium-iodine primary batteries surrounds and contains the iodine depolarizer material

Lithium iodide provides a good example of a solid (Figure 24.14). This depolarizer material is corrosive

which has a moderately high conductivity owing to the stainless steel case and must be kept from

to a large number of mobile cation vacancies. In contacting the case for maximum cell life. A second

Figure 24.13 the movement of such a defect from left barrier, formed from fluorocarbon plastics, surrounds

to right is seen to result in the net transfer of a positive the lithium envelope, insulates it from the case, and

charge from right to left, i.e. the Li' vacancy behaves provides a second envelope for the containment of the

in effect as a singly charged anion. depolarizer. The corrosive effect of iodine-containing

Despite its rather modest ambient conductivity depolarizer on stainless steel is lower than that of

(5 x lO-jS/m), lithium iodide forms the electrolyte depolarizer made with more active halogens, such as

of a battery which is now one of the commonest bromine or chlorine.

power sources for implantable cardiac pacemakers. The modes of failure of this battery are slow. It

The battery is successful in this application since cannot suffer from separator rupture since the lithium

only small currents are drawn (typically 25 PA), thus iodide layer is self-healing. Nor does it suffer from

keeping the iR drop in the cell low. It also meets the electrolyte leakage since the electrolyte is solid.

requirement of long service-life (8-10 years), and the A cell is formed when a lithium anode is brought

high open circuit voltage and low equivalent mass of into contact with a cathode composed of iodine and

lithium guarantee a high energy density, so minimizing P2VP depolarizer. Between these components forms

the weight of the implanted device. Finally, in this all- the third component necessary for any cell-the elec-

solid-state cell, it is possible to avoid many of the trolyte (in this case solid lithium iodide). As cur-

rent is drawn from the cell, lithium is oxidized and

304 stainless Cathode Anode

steel cover lead (+I jad (-)

1 i Hermetic

panel / 1 \ frame

Fluoroplastic Metallic Cathode 304 stainless

enveiope lithium current steel case

anode collector

Figure 24.13 Migration of a cation vacancy within a lithium iodide Figure 24.14 Catalyst Research Corporation model 802/803 solid

lattice, where 0 = Li+ and 0 = I- lithium-iodine cell (Courtesy of Catalyst Research Corporation)