Page 173 - Bebop to The Boolean Boogie An Unconventional Guide to Electronics Fundamentals, Components, and Processes

P. 173

154 Chapter Fourteen

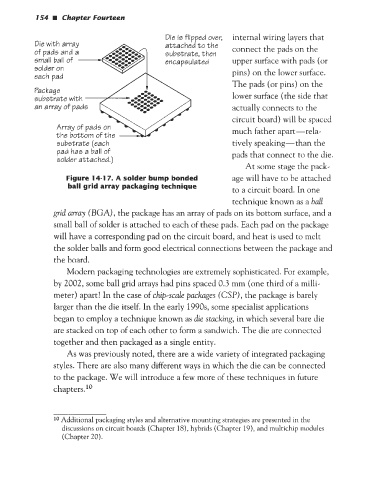

Die is flipped over, internal wiring layers that

attached to the connect the pads on the

substrate, then

upper surface with pads (or

pins) on the lower surface.

The pads (or pins) on the

lower surface (the side that

actually connects to the

circuit board) will be spaced

much father apart-rela-

substrate (each tively speaking-than the

pad has a ball of pads that connect to the die.

solder attached.)

At some stage the pack-

Figure 14-1 7. A solder bump bonded age will have to be attached

ball grid array packaging technique to a circuit board. In one

technique known as a bull

grid array (BGA) , the package has an array of pads on its bottom surface, and a

small ball of solder is attached to each of these pads. Each pad on the package

will have a corresponding pad on the circuit board, and heat is used to melt

the solder balls and form good electrical connections between the package and

the board.

Modern packaging technologies are extremely sophisticated. For example,

by 2002, some ball grid arrays had pins spaced 0.3 mm (one third of a milli-

meter) apart! In the case of chip-scale packages (CSP), the package is barely

larger than the die itself. In the early 1990s, some specialist applications

began to employ a technique known as die stacking, in which several bare die

are stacked on top of each other to form a sandwich. The die are connected

together and then packaged as a single entity.

As was previously noted, there are a wide variety of integrated packaging

styles. There are also many different ways in which the die can be connected

to the package. We will introduce a few more of these techniques in future

chapters. lo

10 Additional packaging styles and alternative mounting strategies are presented in the

discussions on circuit boards (Chapter 18), hybrids (Chapter 19), and multichip modules

(Chapter 20).