Page 170 - Bebop to The Boolean Boogie An Unconventional Guide to Electronics Fundamentals, Components, and Processes

P. 170

Integrated Circuits (ICs) 151

The Packaging Process

The individual integrated circuits are tested while they are still part of the

wafer in a process known as wafer probing. An automated tester places probes on

the device’s pads, applies power to the power pads, injects a series of signals

into the input pads, and monitors the corresponding signals returned from the

output pads. Each integrated circuit is tested in turn, and any device that fails

the tests is automatically tagged with a splash of dye for subsequent rejection.

The yield is the number of devices that pass

tests as a percentage of the total number

fabricated on that wafer.

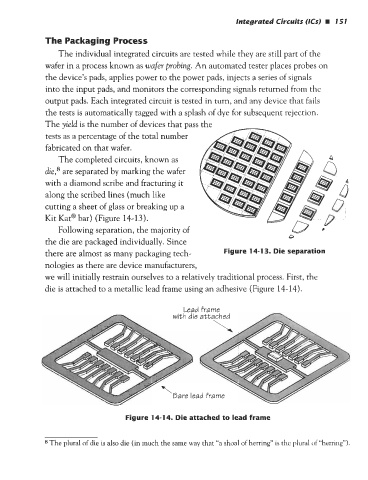

The completed circuits, known as

die,s are separated by marking the wafer

with a diamond scribe and fracturing it

along the scribed lines (much like

cutting a sheet of glass or breaking up a

Kit Kat@ bar) (Figure 14-13).

Following separation, the majority of

the die are packaged individually. Since

there are almost as many packaging tech- Figure 14-1 3. Die separation

nologies as there are device manufacturers,

we will initially restrain ourselves to a relatively traditional process. First, the

die is attached to a metallic lead frame using an adhesive (Figure 14-14).

Lead frame

Bare lead frame

Figure 14-14. Die attached to lead frame

8 The plural of die is also die (in much the same way that “a shoal of herring” is the plural of “herring”).