Page 165 - Bebop to The Boolean Boogie An Unconventional Guide to Electronics Fundamentals, Components, and Processes

P. 165

146 H Chapter Fourteen

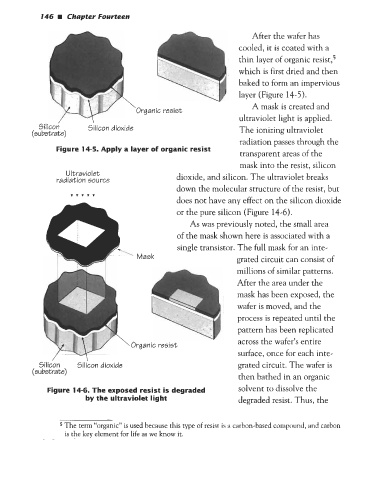

After the wafer has

cooled, it is coated with a

thin layer of organic re~ist,~

which is first dried and then

baked to form an impervious

layer (Figure 14-5).

Organic resist A mask is created and

ultraviolet light is applied.

Silicon

(su bstrate) Silicon dioxide The ionizing ultraviolet

radiation passes through the

Figure 14-5. Apply a layer of organic resist

transparent areas of the

mask into the resist, silicon

Ultraviolet

radiation source dioxide, and silicon. The ultraviolet breaks

down the molecular structure of the resist, but

does not have any effect on the silicon dioxide

or the pure silicon (Figure 14-6).

As was previously noted, the small area

I of the mask shown here is associated with a

single transistor. The full mask for an inte-

Mask grated circuit can consist of

millions of similar patterns.

After the area under the

mask has been exposed, the

wafer is moved, and the

process is repeated until the

pattern has been replicated

Organic resist across the wafer’s entire

surface, once for each inte-

Sili& Silicon dioxide grated circuit. The wafer is

(su bstrate)

then bathed in an organic

Figure 14-6. The exposed resist is degraded solvent to dissolve the

by the ultraviolet light degraded resist. Thus, the

The term “organic” is used because this type of resist is a carbon-based compound, and carbon

is the key element for life as we know it.