Page 164 - Bebop to The Boolean Boogie An Unconventional Guide to Electronics Fundamentals, Components, and Processes

P. 164

Integrated Circuits (ICs) 145

single integrated circuit, which is typically in the region of lmm x lmm to

lOmm x lOmm, but may be even larger. After the area corresponding to one

integrated circuit has been exposed, the wafer is moved and the process is

repeated until the pattern has been replicated across the whole of the wafer’s

surface. This technique for duplicating the pattern is called a step-and-repeat

process.

As we shall see, multiple layers are required to construct the transistors

(and other components), where each layer requires its own unique mask. Once

all of the transistors have been created, similar techniques are used to lay down

the tracking (wiring) layers that connect the transistors together.

A More Detailed Look at the Fabrication Process

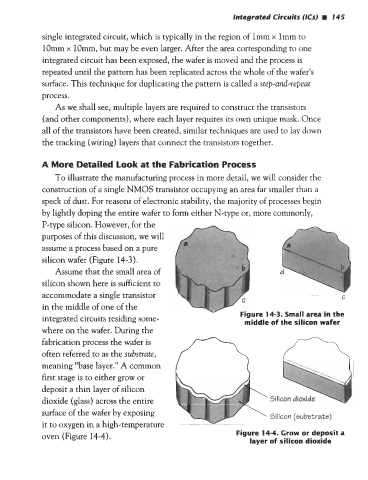

To illustrate the manufacturing process in more detail, we will consider the

construction of a single NMOS transistor occupying an area far smaller than a

speck of dust. For reasons of electronic stability, the majority of processes begin

by lightly doping the entire wafer to form either N-type or, more commonly,

P-type silicon. However, for the

purposes of this discussion, we will

assume a process based on a pure

silicon wafer (Figure 14-3).

Assume that the small area of

silicon shown here is sufficient to

accommodate a single transistor

in the middle of one of the

integrated circuits residing some- middle of the silicon wafer

where on the wafer. During the

fabrication process the wafer is

often referred to as the substrate,

meaning “base layer.” A common

first stage is to either grow or

deposit a thin layer of silicon

dioxide (glass) across the entire

surface of the wafer by exposing

it to oxygen in a high-temperature

oven (Figure 14-4). Figure 14-4. Grow or deposit a

layer of silicon dioxide