Page 167 - Bebop to The Boolean Boogie An Unconventional Guide to Electronics Fundamentals, Components, and Processes

P. 167

148 rn Chapter Fourteen

Gas containinq The remaining silicon

dioxide layer is removed

by means of an appropri-

ate solvent that doesn’t

affect the silicon sub-

strate (including the

doped regions). Then

additional masks and

variations on the process

are used to create two

(substrate)

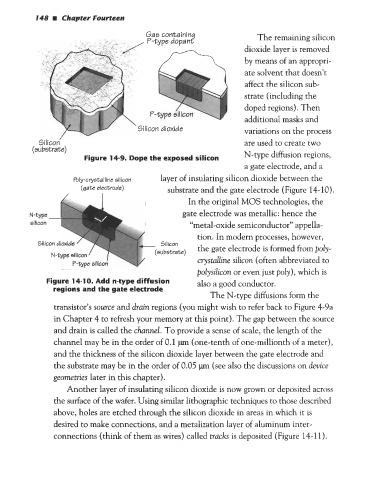

Figure 14-9. Dope the exposed silicon N-type diffusion regions,

a gate electrode, and a

Poly-crystalline silicon layer of insulating silicon dioxide between the

(gate electrode) substrate and the gate electrode (Figure 14-10).

/ I

In the original MOS technologies, the

gate electrode was metallic: hence the

“metal-oxide semiconductor” appella-

tion. In modern processes, however,

- Silicon

(substrate) the gate electrode is formed from poly-

crystalline silicon (often abbreviated to

polysilicon or even just poly), which is

Figure 14-1 0. Add n-type diffusion also a good conductor.

regions and the gate electrode

The N-type diffusions form the

transistor’s source and drain regions (you might wish to refer back to Figure 4-9a

in Chapter 4 to refresh your memory at this point). The gap between the source

and drain is called the channel. To provide a sense of scale, the length of the

channel may be in the order of 0.1 pm (one-tenth of one-millionth of a meter),

and the thickness of the silicon dioxide layer between the gate electrode and

the substrate may be in the order of 0.05 pm (see also the discussions on dewice

geometries later in this chapter).

Another layer of insulating silicon dioxide is now grown or deposited across

the surface of the wafer. Using similar lithographic techniques to those described

above, holes are etched through the silicon dioxide in areas in which it is

desired to make connections, and a metalization layer of aluminum inter-

connections (think of them as wires) called tracks is deposited (Figure 14-1 1).