Page 356 - Biaxial Multiaxial Fatigue and Fracture

P. 356

340 S. POMMIER

9. Savage, S.B. (1997). Problems in the static and dynamics of granular materials. In: Powder

and grains, pp. 185-194, Behringer, R.P. and Jenkins, J.T. (Eds.), Balkema, Rotterdam.

10. Dantu, P. (1968). Etude statistique des forces intergranulaires dans un milieu pulvkrulent.

Giotechnique. 18.50-55

11. Radjai, F., Wolf, D.E., Roux, S., Jean, M. and Moreau, J.J. (1997). Force networks in

dense granular media. In: Powder and grains, pp. 21 1-214, Behringer, R.P. and Jenkins,

J.T. (Eds.), Rotterdam.

12. Roux, J.N. (1997). Contact disorder and nonlinear elasticity of granular packings: A simple

model. In: Powder and grains, pp. 215-218, Behringer, R.P. and Jenkins, J.T. (Eds.),

Balkema, Rotterdam.

13. Le Biavant, K., Pommier, S. and Prioul, C. (1999), Ghost structure effect on fatigue crack

initiation and growth in a Ti-6A1-4V alloy. In : Titane 99:Science and technology, pp 48 1-

487, Goryin, LV. and Ushkov, S.S. (Eds), Saint Petersburg, Russia.

14. Le Biavant, K., Pommier, S. and Prioul, C. (2002). Local texture and fatigue crack

initiation in a Ti-6A1-4V Titanium alloy. Fat. Fract. Engng. Mater. Struct 25,527-545.

15. Pommier, S. (2002). “Arching” effect in elastic polycrystals. Fat. Fract. Engng. Mater.

Struct. 25,331-348.

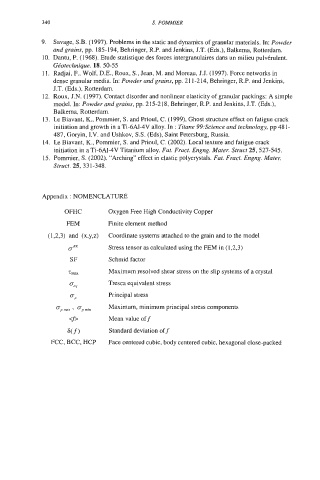

Appendix : NOMENCLATURE

Oxygen Free High Conductivity Copper

Finite element method

Coordinate systems attached to the grain and to the model

Stress tensor as calculated using the FEM in (1,2,3)

Schmid factor

Maximum resolved shear stress on the slip systems of a crystal

Tresca equivalent stress

Principal stress

Maximum, minimum principal stress components

Mean value off

Standard deviation off

Face centered cubic, body centered cubic, hexagonal close-packed