Page 505 - Biaxial Multiaxial Fatigue and Fracture

P. 505

489

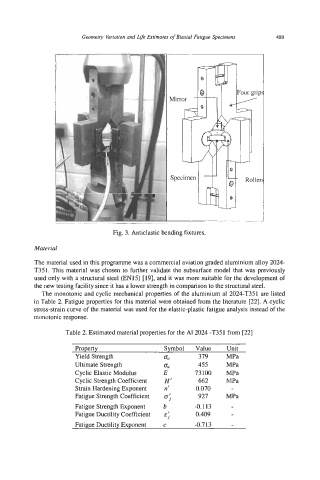

Fig. 3. Anticlastic bending fixtures.

Material

The material used in this programme was a commercial aviation graded aluminium alloy 2024-

T351. This material was chosen to further validate the subsurface model that was previously

used only with a structural steel (EN15) [19], and it was more suitable for the development of

the new testing facility since it has a lower strength in comparison to the structural steel.

The monotonic and cyclic mechanical properties of the aluminium al 2024-T351 are listed

in Table 2. Fatigue properties for this material were obtained from the literature [22]. A cyclic

stress-strain curve of the material was used for the elastic-plastic fatigue analysis instead of the

monotonic response.

Table 2. Estimated material properties for the AI 2024 -T351 from [22]

Property Symbol Value Unit

Yield Strength 00 379 MPa

Ultimate Strength 0, 455 MPa

Cyclic Elastic Modulus E 73100 MPa

Cyclic Strength Coefficient H' 662 MPa

Strain Hardening Exponent n' 0.070

Fatigue Strength Coefficient 0; 927 MPa

Fatigue Strength Exponent b -0.113

Fatigue Ductility Coefficient E; 0.409

Fatigue Ductility Exponent c -0.713