Page 338 - Biodegradable Polyesters

P. 338

316 12 Biodegradable Polyesters Polymer–Polymer Composites

10 9 8 PLLA/PGA MFC (70/30 by wt)

Storage modulus (E′) (GPa) 7 6 5 4 3

PLLA/PGA MFC (80/20 by wt)

PLLA

0 2 1

20 30 40 50 60 70 80

(a) Temperature (°C)

1200 PLLA/PGA MFC (70/30 by wt)

PLLA/PGA MFC (80/20 by wt)

Loss modulus (E′′) (MPa) 800

1000

PLLA

600

400

200

0

20 30 40 50 60 70 80

(b) Temperature (°C)

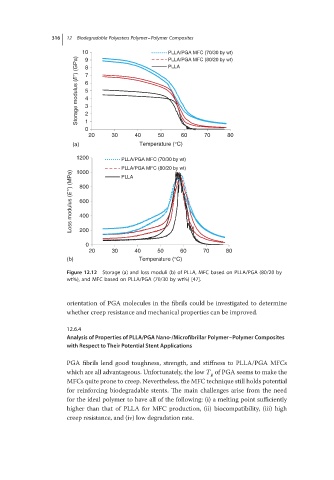

Figure 12.12 Storage (a) and loss moduli (b) of PLLA, MFC based on PLLA/PGA (80/20 by

wt%), and MFC based on PLLA/PGA (70/30 by wt%) [47].

orientation of PGA molecules in the fibrils could be investigated to determine

whether creep resistance and mechanical properties can be improved.

12.6.4

Analysis of Properties of PLLA/PGA Nano-/Microfibrillar Polymer–Polymer Composites

with Respect to Their Potential Stent Applications

PGA fibrils lend good toughness, strength, and stiffness to PLLA/PGA MFCs

which are all advantageous. Unfortunately, the low T of PGA seems to make the

g

MFCs quite prone to creep. Nevertheless, the MFC technique still holds potential

for reinforcing biodegradable stents. The main challenges arise from the need

for the ideal polymer to have all of the following: (i) a melting point sufficiently

higher than that of PLLA for MFC production, (ii) biocompatibility, (iii) high

creep resistance, and (iv) low degradation rate.