Page 334 - Biodegradable Polyesters

P. 334

312 12 Biodegradable Polyesters Polymer–Polymer Composites

Aluminium plates Teflon sheets

Spacers

PLLA/PGA

wire

(a)

Quench to

room

temperature

between

aluminium

Heated platens blocks

T = 185 °C

(b) (c)

(d)

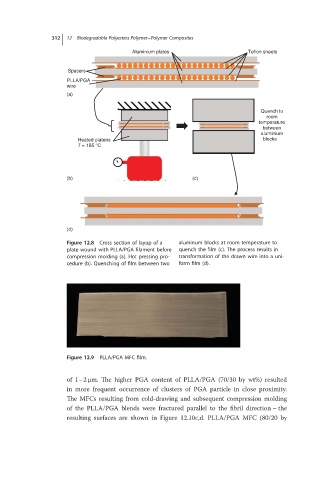

Figure 12.8 Cross section of layup of a aluminum blocks at room temperature to

plate wound with PLLA/PGA filament before quench the film (c). The process results in

compression molding (a). Hot pressing pro- transformation of the drawn wire into a uni-

cedure (b). Quenching of film between two form film (d).

Figure 12.9 PLLA/PGA MFC film.

of 1–2 μm. The higher PGA content of PLLA/PGA (70/30 by wt%) resulted

in more frequent occurrence of clusters of PGA particle in close proximity.

The MFCs resulting from cold-drawing and subsequent compression molding

of the PLLA/PGA blends were fractured parallel to the fibril direction – the

resulting surfaces are shown in Figure 12.10c,d. PLLA/PGA MFC (80/20 by