Page 319 - Biomedical Engineering and Design Handbook Volume 2, Applications

P. 319

THE PRINCIPLES OF X-RAY COMPUTED TOMOGRAPHY 297

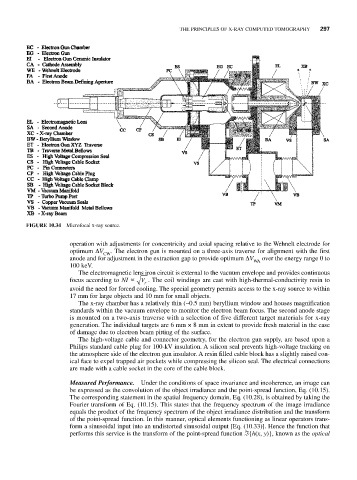

FIGURE 10.34 Microfocal x-ray source.

operation with adjustments for concentricity and axial spacing relative to the Wehnelt electrode for

optimum ΔV . The electron gun is mounted on a three-axis traverse for alignment with the first

CW

anode and for adjustment in the extraction gap to provide optimum ΔV over the energy range 0 to

WA

100 keV.

The electromagnetic lens iron circuit is external to the vacuum envelope and provides continuous

focus according to NI V . The coil windings are cast with high-thermal-conductivity resin to

r

avoid the need for forced cooling. The special geometry permits access to the x-ray source to within

17 mm for large objects and 10 mm for small objects.

The x-ray chamber has a relatively thin (~0.5 mm) beryllium window and houses magnification

standards within the vacuum envelope to monitor the electron beam focus. The second anode stage

is mounted on a two-axis traverse with a selection of five different target materials for x-ray

generation. The individual targets are 6 mm × 8 mm in extent to provide fresh material in the case

of damage due to electron beam pitting of the surface.

The high-voltage cable and connector geometry, for the electron gun supply, are based upon a

Philips standard cable plug for 100-kV insulation. A silicon seal prevents high-voltage tracking on

the atmosphere side of the electron gun insulator. A resin filled cable block has a slightly raised con-

ical face to expel trapped air pockets while compressing the silicon seal. The electrical connections

are made with a cable socket in the core of the cable block.

Measured Performance. Under the conditions of space invariance and incoherence, an image can

be expressed as the convolution of the object irradiance and the point-spread function, Eq. (10.15).

The corresponding statement in the spatial frequency domain, Eq. (10.28), is obtained by taking the

Fourier transform of Eq. (10.15). This states that the frequency spectrum of the image irradiance

equals the product of the frequency spectrum of the object irradiance distribution and the transform

of the point-spread function. In this manner, optical elements functioning as linear operators trans-

form a sinusoidal input into an undistorted sinusoidal output [Eq. (10.33)]. Hence the function that

performs this service is the transform of the point-spread function ℑ{h(x, y)}, known as the optical