Page 324 - Biomedical Engineering and Design Handbook Volume 2, Applications

P. 324

302 DIAGNOSTIC EQUIPMENT DESIGN

This is a very inefficient process with most of the energy appearing as heat. As a consequence, the

temperature of the target material can reach melting point. The liquid metal is subsequently removed

by electron beam pressure, resulting in the excavation of a pit or groove. This degradation of the tar-

get material creates an enlarged focal spot. Therefore, it is important to determine the maximum

power density that a target material can safely accommodate in order to produce maximum x-ray

flux to satisfy the threshold of detection condition [Eq. (10.91)].

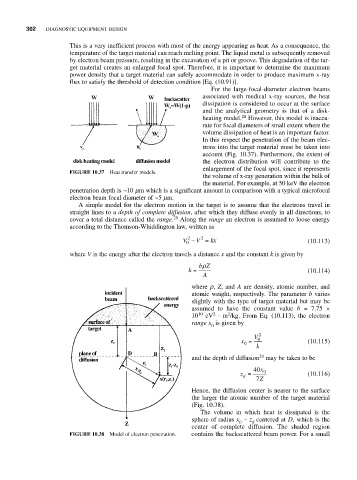

For the large-focal-diameter electron beams

associated with medical x-ray sources, the heat

dissipation is considered to occur at the surface

and the analytical geometry is that of a disk-

heating model. 28 However, this model is inaccu-

rate for focal diameters of small extent where the

volume dissipation of heat is an important factor.

In this respect the penetration of the beam elec-

trons into the target material must be taken into

account (Fig. 10.37). Furthermore, the extent of

the electron distribution will contribute to the

enlargement of the focal spot, since it represents

FIGURE 10.37 Heat transfer models.

the volume of x-ray generation within the bulk of

the material. For example, at 50 keV the electron

penetration depth is ~10 mm which is a significant amount in comparison with a typical microfocal

electron beam focal diameter of ~5 mm.

A simple model for the electron motion in the target is to assume that the electrons travel in

straight lines to a depth of complete diffusion, after which they diffuse evenly in all directions, to

29

cover a total distance called the range. Along the range an electron is assumed to loose energy

according to the Thomson-Whiddington law, written as

2

2

V − V = kx (10.113)

0

where V is the energy after the electron travels a distance x and the constant k is given by

ρ

bZ

k = (10.114)

A

where r, Z, and A are density, atomic number, and

atomic weight, respectively. The parameter b varies

slightly with the type of target material but may be

assumed to have the constant value b = 7.75 ×

2

2

10 10 eV ⋅ m /kg. From Eq. (10.113), the electron

range x is given by

0

V 2

x = 0 (10.115)

0

k

29

and the depth of diffusion may be taken to be

40 x

z = 0 (10.116)

d

7 Z

Hence, the diffusion center is nearer to the surface

the larger the atomic number of the target material

(Fig. 10.38).

The volume in which heat is dissipated is the

sphere of radius x − z centered at D, which is the

0

d

center of complete diffusion. The shaded region

FIGURE 10.38 Model of electron penetration. contains the backscattered beam power. For a small