Page 348 - Boiler_Operators_Handbook,_Second_Edition

P. 348

Plants and Equipment 333

the motor. Reciprocating Pumps

I did say there’s a standard formula for pump Many boiler plant applications were predominantly

horsepower. There is, it’s called Hydraulic Horsepower, served by reciprocating piston pumps until the middle

th

is also called theoretical horsepower, and it can be cal- of the 20 century when multi-stage centrifugal pumps

culated by multiplying the flow in gallons per minute displaced them. For that matter most of the liquids in

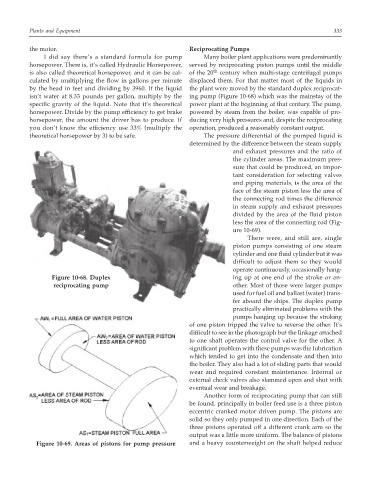

by the head in feet and dividing by 3960. If the liquid the plant were moved by the standard duplex reciprocat-

isn’t water at 8.33 pounds per gallon, multiply by the ing pump (Figure 10-68) which was the mainstay of the

specific gravity of the liquid. Note that it’s theoretical power plant at the beginning of that century. The pump,

horsepower. Divide by the pump efficiency to get brake powered by steam from the boiler, was capable of pro-

horsepower, the amount the driver has to produce. If ducing very high pressures and, despite the reciprocating

you don’t know the efficiency use 33% (multiply the operation, produced a reasonably constant output.

theoretical horsepower by 3) to be safe. The pressure differential of the pumped liquid is

determined by the difference between the steam supply

and exhaust pressures and the ratio of

the cylinder areas. The maximum pres-

sure that could be produced, an impor-

tant consideration for selecting valves

and piping materials, is the area of the

face of the steam piston less the area of

the connecting rod times the difference

in steam supply and exhaust pressures

divided by the area of the fluid piston

less the area of the connecting rod (Fig-

ure 10-69).

There were, and still are, single

piston pumps consisting of one steam

cylinder and one fluid cylinder but it was

difficult to adjust them so they would

operate continuously, occasionally hang-

Figure 10-68. Duplex ing up at one end of the stroke or an-

reciprocating pump other. Most of those were larger pumps

used for fuel oil and ballast (water) trans-

fer aboard the ships. The duplex pump

practically eliminated problems with the

pumps hanging up because the stroking

of one piston tripped the valve to reverse the other. It’s

difficult to see in the photograph but the linkage attached

to one shaft operates the control valve for the other. A

significant problem with these pumps was the lubrication

which tended to get into the condensate and then into

the boiler. They also had a lot of sliding parts that would

wear and required constant maintenance. Internal or

external check valves also slammed open and shut with

eventual wear and breakage.

Another form of reciprocating pump that can still

be found, principally in boiler feed use is a three piston

eccentric cranked motor driven pump. The pistons are

solid so they only pumped in one direction. Each of the

three pistons operated off a different crank arm so the

output was a little more uniform. The balance of pistons

Figure 10-69. Areas of pistons for pump pressure and a heavy counterweight on the shaft helped reduce