Page 20 - Boiler plant and distribution system optimization manual

P. 20

Boiler Plant Orientation 5

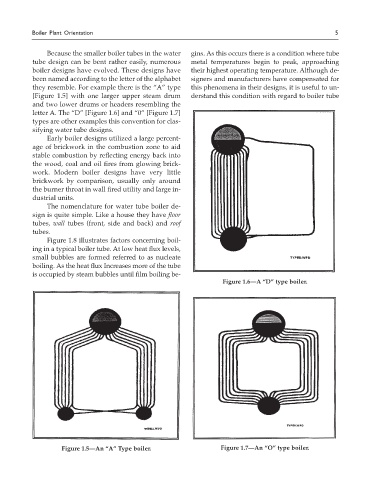

Because the smaller boiler tubes in the water gins. As this occurs there is a condition where tube

tube design can be bent rather easily, numerous metal temperatures begin to peak, approaching

boiler designs have evolved. These designs have their highest operating temperature. Although de-

been named according to the letter of the alphabet signers and manufacturers have compensated for

they resemble. For example there is the “A” type this phenomena in their designs, it is useful to un-

[Figure 1.5] with one larger upper steam drum derstand this condition with regard to boiler tube

and two lower drums or headers resembling the

letter A. The “D” [Figure 1.6] and “0” [Figure 1.7]

types are other examples this convention for clas-

sifying water tube designs.

Early boiler designs utilized a large percent-

age of brickwork in the combustion zone to aid

stable combustion by reflecting energy back into

the wood, coal and oil fires from glowing brick-

work. Modern boiler designs have very little

brickwork by comparison, usually only around

the burner throat in wall fired utility and large in-

dustrial units.

The nomenclature for water tube boiler de-

sign is quite simple. Like a house they have floor

tubes, wall tubes (front, side and back) and roof

tubes.

Figure 1.8 illustrates factors concerning boil-

ing in a typical boiler tube. At low heat flux levels,

small bubbles are formed referred to as nucleate

boiling. As the heat flux Increases more of the tube

is occupied by steam bubbles until film boiling be-

Figure 1.6—A “D” type boiler.

Figure 1.5—An “A” Type boiler. Figure 1.7—An “O” type boiler.