Page 216 - Cam Design Handbook

P. 216

THB7 8/15/03 1:58 PM Page 204

204 CAM DESIGN HANDBOOK

7.6 CASE STUDIES

We introduce below two case studies illustrating the application of the concepts introduced

in this chapter.

7.6.1 Cam-Size Minimization

We illustrate here a methodology that allows the designer to minimize the overall size of

planar cam mechanisms while maintaining an acceptable force-transmission performance

on imposing bounds on the pressure angle. This methodology has some improvements

over other techniques, e.g., the exploratory search method proposed in Chan and Kok

(1996).

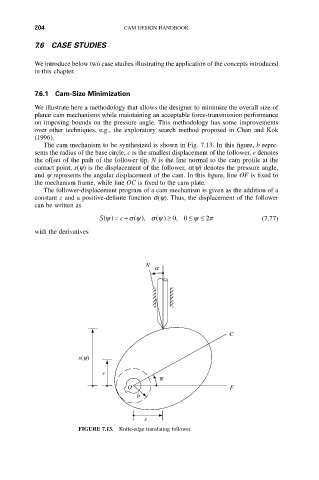

The cam mechanism to be synthesized is shown in Fig. 7.13. In this figure, b repre-

sents the radius of the base circle, c is the smallest displacement of the follower, e denotes

the offset of the path of the follower tip, N is the line normal to the cam profile at the

contact point, s(y) is the displacement of the follower, a(y) denotes the pressure angle,

and y represents the angular displacement of the cam. In this figure, line OF is fixed to

the mechanism frame, while line OC is fixed to the cam plate.

The follower-displacement program of a cam mechanism is given as the addition of a

constant c and a positive-definite function s(y). Thus, the displacement of the follower

can be written as

c

0

s y

S y () =+ (), s y () ≥ , 0 £ y £ 2 p (7.77)

with the derivatives

N

a

C

s(y)

c

y

O F

b

e

FIGURE 7.13. Knife-edge translating follower.