Page 307 - Cam Design Handbook

P. 307

THB10 9/19/03 7:28 PM Page 295

CAM MANUFACTURING 295

± Tolerance in x direction

Actual cam Desired profile

profile

Normal

distribution

curve ± Tolerance lines

in Y direction

Dq

Actual machine

setting point

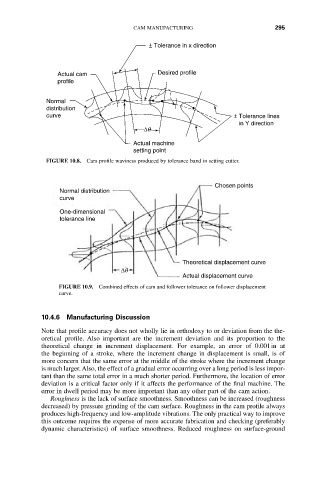

FIGURE 10.8. Cam profile waviness produced by tolerance band in setting cutter.

Chosen points

Normal distribution

curve

One-dimensional

tolerance line

Theoretical displacement curve

Dq

Actual displacement curve

FIGURE 10.9. Combined effects of cam and follower tolerance on follower displacement

curve.

10.4.6 Manufacturing Discussion

Note that profile accuracy does not wholly lie in orthodoxy to or deviation from the the-

oretical profile. Also important are the increment deviation and its proportion to the

theoretical change in increment displacement. For example, an error of 0.001in at

the beginning of a stroke, where the increment change in displacement is small, is of

more concern that the same error at the middle of the stroke where the increment change

is much larger. Also, the effect of a gradual error occurring over a long period is less impor-

tant than the same total error in a much shorter period. Furthermore, the location of error

deviation is a critical factor only if it affects the performance of the final machine. The

error in dwell period may be more important than any other part of the cam action.

Roughness is the lack of surface smoothness. Smoothness can be increased (roughness

decreased) by pressure grinding of the cam surface. Roughness in the cam profile always

produces high-frequency and low-amplitude vibrations. The only practical way to improve

this outcome requires the expense of more accurate fabrication and checking (preferably

dynamic characteristics) of surface smoothness. Reduced roughness on surface-ground