Page 304 - Cam Design Handbook

P. 304

THB10 9/19/03 7:28 PM Page 292

292 CAM DESIGN HANDBOOK

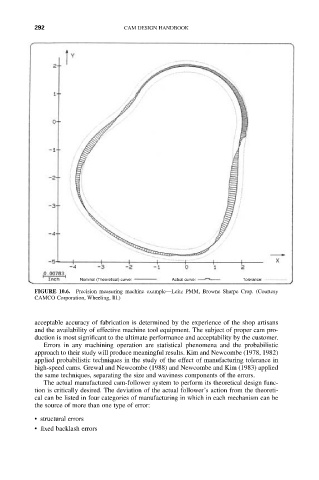

Nominal (Theoretical) curve: Actual curve: Tolerance:

FIGURE 10.6. Precision measuring machine example—Leitz PMM, Browne Sharpe Crop. (Courtesy

CAMCO Corporation, Wheeling, Ill.)

acceptable accuracy of fabrication is determined by the experience of the shop artisans

and the availability of effective machine tool equipment. The subject of proper cam pro-

duction is most significant to the ultimate performance and acceptability by the customer.

Errors in any machining operation are statistical phenomena and the probabilistic

approach to their study will produce meaningful results. Kim and Newcombe (1978, 1982)

applied probabilistic techniques in the study of the effect of manufacturing tolerance in

high-speed cams. Grewal and Newcombe (1988) and Newcombe and Kim (1983) applied

the same techniques, separating the size and waviness components of the errors.

The actual manufactured cam-follower system to perform its theoretical design func-

tion is critically desired. The deviation of the actual follower’s action from the theoreti-

cal can be listed in four categories of manufacturing in which in each mechanism can be

the source of more than one type of error:

• structural errors

• fixed backlash errors