Page 487 - Cam Design Handbook

P. 487

THB14 9/19/03 7:58 PM Page 475

SPECIAL CAM MECHANISMS 475

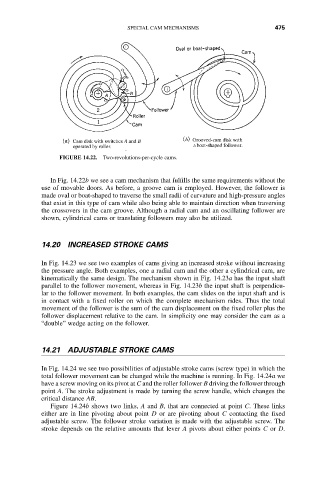

FIGURE 14.22. Two-revolutions-per-cycle cams.

In Fig. 14.22b we see a cam mechanism that fulfills the same requirements without the

use of movable doors. As before, a groove cam is employed. However, the follower is

made oval or boat-shaped to traverse the small radii of curvature and high-pressure angles

that exist in this type of cam while also being able to maintain direction when traversing

the crossovers in the cam groove. Although a radial cam and an oscillating follower are

shown, cylindrical cams or translating followers may also be utilized.

14.20 INCREASED STROKE CAMS

In Fig. 14.23 we see two examples of cams giving an increased stroke without increasing

the pressure angle. Both examples, one a radial cam and the other a cylindrical cam, are

kinematically the same design. The mechanism shown in Fig. 14.23a has the input shaft

parallel to the follower movement, whereas in Fig. 14.23b the input shaft is perpendicu-

lar to the follower movement. In both examples, the cam slides on the input shaft and is

in contact with a fixed roller on which the complete mechanism rides. Thus the total

movement of the follower is the sum of the cam displacement on the fixed roller plus the

follower displacement relative to the cam. In simplicity one may consider the cam as a

“double” wedge acting on the follower.

14.21 ADJUSTABLE STROKE CAMS

In Fig. 14.24 we see two possibilities of adjustable stroke cams (screw type) in which the

total follower movement can be changed while the machine is running. In Fig. 14.24a we

have a screw moving on its pivot at C and the roller follower B driving the follower through

point A. The stroke adjustment is made by turning the screw handle, which changes the

critical distance AB.

Figure 14.24b shows two links, A and B, that are connected at point C. These links

either are in line pivoting about point D or are pivoting about C contacting the fixed

adjustable screw. The follower stroke variation is made with the adjustable screw. The

stroke depends on the relative amounts that lever A pivots about either points C or D.