Page 229 - Carbon Nanotube Fibres and Yarns

P. 229

220 Carbon Nanotube Fibers and Yarns

0.5

Twist Recovery

0.0

–0.5

∆R/R 0 –1.0

Twist release

–1.5

–2.0

–2.5

0 100 200 300

(A) t (s)

60

Permanent

40 change in R

20

DR/R 0 (%) 0 Release

–20 Recovery

–40

–60

0 1 2 3 4 5 6 7

(B) t (min)

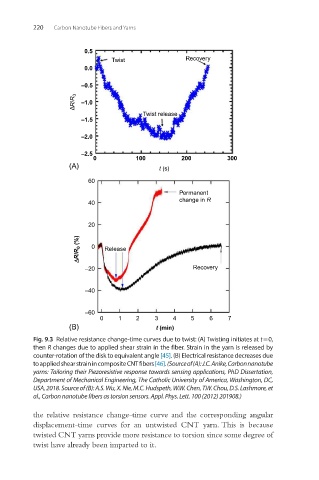

Fig. 9.3 Relative resistance change-time curves due to twist: (A) Twisting initiates at t = 0,

then R changes due to applied shear strain in the fiber. Strain in the yarn is released by

counter- rotation of the disk to equivalent angle [45]. (B) Electrical resistance decreases due

to applied shear strain in composite CNT fibers [46]. (Source of (A): J.C. Anike, Carbon nanotube

yarns: Tailoring their Piezoresistive response towards sensing applications, PhD Dissertation,

Department of Mechanical Engineering, The Catholic University of America, Washington, DC,

USA, 2018. Source of (B): A.S. Wu, X. Nie, M.C. Hudspeth, W.W. Chen, T.W. Chou, D.S. Lashmore, et

al., Carbon nanotube fibers as torsion sensors. Appl. Phys. Lett. 100 (2012) 201908.)

the relative resistance change-time curve and the corresponding angular

displacement-time curves for an untwisted CNT yarn. This is because

twisted CNT yarns provide more resistance to torsion since some degree of

twist have already been imparted to it.