Page 232 - Carbon Nanotube Fibres and Yarns

P. 232

Sensors based on CNT yarns 223

400

3 2 CNT fiber prestrain

No

Relative change in resistance 350 1 0 0 100 200 300 100 %

only

300

250

200

prestrain

400

150

100

50

0

0 100 200 300 400 500 600 700 800 900 1000

(A) 8000 Strain (%)

Relative change in resistance (%) 6000

4000

2000

0

0 5 10 15

Strain (%)

(B)

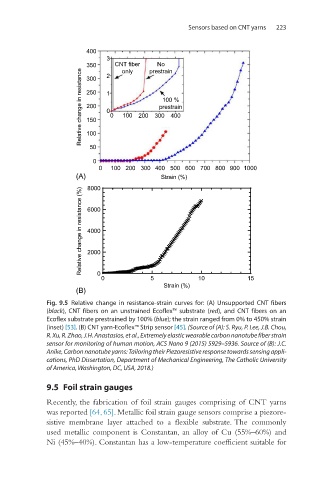

Fig. 9.5 Relative change in resistance-strain curves for: (A) Unsupported CNT fibers

(black), CNT fibers on an unstrained Ecoflex™ substrate (red), and CNT fibers on an

Ecoflex substrate prestrained by 100% (blue); the strain ranged from 0% to 450% strain

(inset) [53]. (B) CNT yarn-Ecoflex™ Strip sensor [45]. (Source of (A): S. Ryu, P. Lee, J.B. Chou,

R. Xu, R. Zhao, J.H. Anastasios, et al., Extremely elastic wearable carbon nanotube fiber strain

sensor for monitoring of human motion, ACS Nano 9 (2015) 5929–5936. Source of (B): J.C.

Anike, Carbon nanotube yarns: Tailoring their Piezoresistive response towards sensing appli-

cations, PhD Dissertation, Department of Mechanical Engineering, The Catholic University

of America, Washington, DC, USA, 2018.)

9.5 Foil strain gauges

Recently, the fabrication of foil strain gauges comprising of CNT yarns

was reported [64, 65]. Metallic foil strain gauge sensors comprise a piezore-

sistive membrane layer attached to a flexible substrate. The commonly

used metallic component is Constantan, an alloy of Cu (55%–60%) and

Ni (45%–40%). Constantan has a low-temperature coefficient suitable for