Page 230 - Carbon Nanotube Fibres and Yarns

P. 230

Sensors based on CNT yarns 221

¥10 6 2.0 10

Relative resistance

change 8

1.5

Theta 6

∆R/R 0 1.0 4 θ(°)

0.5

2

0.0 0

0 1 2 3

t(s)

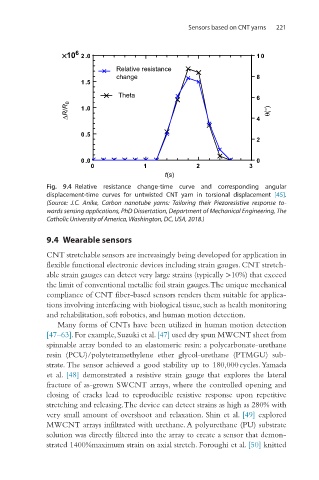

Fig. 9.4 Relative resistance change-time curve and corresponding angular

displacement-time curves for untwisted CNT yarn in torsional displacement [45].

(Source: J.C. Anike, Carbon nanotube yarns: Tailoring their Piezoresistive response to-

wards sensing applications, PhD Dissertation, Department of Mechanical Engineering, The

Catholic University of America, Washington, DC, USA, 2018.)

9.4 Wearable sensors

CNT stretchable sensors are increasingly being developed for application in

flexible functional electronic devices including strain gauges. CNT stretch-

able strain gauges can detect very large strains (typically >10%) that exceed

the limit of conventional metallic foil strain gauges. The unique mechanical

compliance of CNT fiber-based sensors renders them suitable for applica-

tions involving interfacing with biological tissue, such as health monitoring

and rehabilitation, soft robotics, and human motion detection.

Many forms of CNTs have been utilized in human motion detection

[47–63]. For example, Suzuki et al. [47] used dry spun MWCNT sheet from

spinnable array bonded to an elastomeric resin: a polycarbonate- urethane

resin (PCU)/polytetramethylene ether glycol-urethane (PTMGU) sub-

strate. The sensor achieved a good stability up to 180,000 cycles. Yamada

et al. [48] demonstrated a resistive strain gauge that explores the lateral

fracture of as-grown SWCNT arrays, where the controlled opening and

closing of cracks lead to reproducible resistive response upon repetitive

stretching and releasing. The device can detect strains as high as 280% with

very small amount of overshoot and relaxation. Shin et al. [49] explored

MWCNT arrays infiltrated with urethane. A polyurethane (PU) substrate

solution was directly filtered into the array to create a sensor that demon-

strated 1400%maximum strain on axial stretch. Foroughi et al. [50] knitted