Page 171 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 171

134 Carraher’s Polymer Chemistry

OH R OH R

O

+ (4.88)

H H

CH 3 CH 3

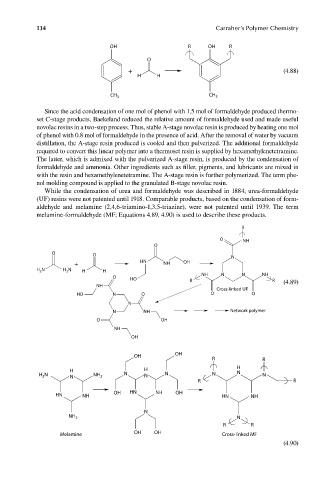

Since the acid condensation of one mol of phenol with 1.5 mol of formaldehyde produced thermo-

set C-stage products, Baekeland reduced the relative amount of formaldehyde used and made useful

novolac resins in a two-step process. Thus, stable A-stage novolac resin is produced by heating one mol

of phenol with 0.8 mol of formaldehyde in the presence of acid. After the removal of water by vacuum

distillation, the A-stage resin produced is cooled and then pulverized. The additional formaldehyde

required to convert this linear polymer into a thermoset resin is supplied by hexamethylenetetramine.

The latter, which is admixed with the pulverized A-stage resin, is produced by the condensation of

formaldehyde and ammonia. Other ingredients such as filler, pigments, and lubricants are mixed in

with the resin and hexamethylenetetramine. The A-stage resin is further polymerized. The term phe-

nol molding compound is applied to the granulated B-stage novolac resin.

While the condensation of urea and formaldehyde was described in 1884, urea-formaldehyde

(UF) resins were not patented until 1918. Comparable products, based on the condensation of form-

aldehyde and melamine (2,4,6-triamino-1,3,5-triazine), were not patented until 1939. The term

melamine-formaldehyde (MF; Equations 4.89, 4.90) is used to describe these products.

R

O NH

O

O O

N

+ HN NH OH

H 2 N H 2 N H H

NH N N NH

O HO R R

NH (4.89)

Cross-linked UF

HO N O O O

N

N NH Network polymer

O OH

NH

OH

OH OH

R R

H H H

N NH N N N N N

H 2 N

N 2

R R

OH HN NH OH

HN NH HN NH

N

NH 2 N

R R

Melamine OH OH Cross-linked MF

(4.90)

9/14/2010 3:38:35 PM

K10478.indb 134

K10478.indb 134 9/14/2010 3:38:35 PM