Page 83 - Chalcogenide Glasses for Infrared Optics

P. 83

Chalcogenide Glasses 61

To welder power

supply (±)

Glass window

Ar in

1/2 Ar ATM.

Samples

Copper plate W tip

Arc

Ti

Chill water in Water out

H O

2

To welder power

supply (±)

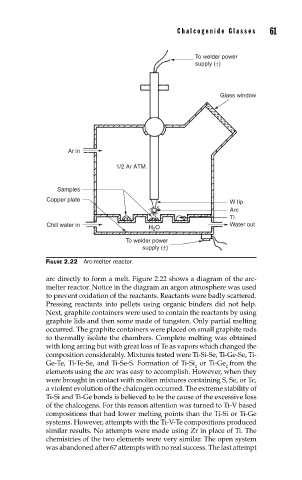

FIGURE 2.22 Arc-melter reactor.

arc directly to form a melt. Figure 2.22 shows a diagram of the arc-

melter reactor. Notice in the diagram an argon atmosphere was used

to prevent oxidation of the reactants. Reactants were badly scattered.

Pressing reactants into pellets using organic binders did not help.

Next, graphite containers were used to contain the reactants by using

graphite lids and then some made of tungsten. Only partial melting

occurred. The graphite containers were placed on small graphite rods

to thermally isolate the chambers. Complete melting was obtained

with long arcing but with great loss of Te as vapors which changed the

composition considerably. Mixtures tested were Ti-Si-Se, Ti-Ge-Se, Ti-

Ge-Te, Ti-Te-Se, and Ti-Se-S. Formation of Ti-Si or Ti-Ge from the

2 2

elements using the arc was easy to accomplish. However, when they

were brought in contact with molten mixtures containing S, Se, or Te,

a violent evolution of the chalcogen occurred. The extreme stability of

Ti-Si and Ti-Ge bonds is believed to be the cause of the excessive loss

of the chalcogens. For this reason attention was turned to Ti-V based

compositions that had lower melting points than the Ti-Si or Ti-Ge

systems. However, attempts with the Ti-V-Te compositions produced

similar results. No attempts were made using Zr in place of Ti. The

chemistries of the two elements were very similar. The open system

was abandoned after 67 attempts with no real success. The last attempt