Page 180 - Chemical Process Equipment - Selection and Design

P. 180

152 FLUID TRANSPORT EQUIPMENT

140

120

100

80

z

60

40

20

'0 IO 20 30 40 50 60 70 80 90 130

Wide Open Volume,%

(a)

Curved

Backwardly Radial Forwardly

Curved Blade

s-

First Cost* ............ High Medium Low

Efficiency. ............

Stability of Operation.. . High Medium Low

Poor

Good

Good

Space Required. ....... Medium Medium Small

Tip Speed.. ........... High Medium Low

Resistance to Abrasion.. Medium Good Poor

Ability to Handle

Sticky Materials. .... Medium Good

Wide Open Volume ,%

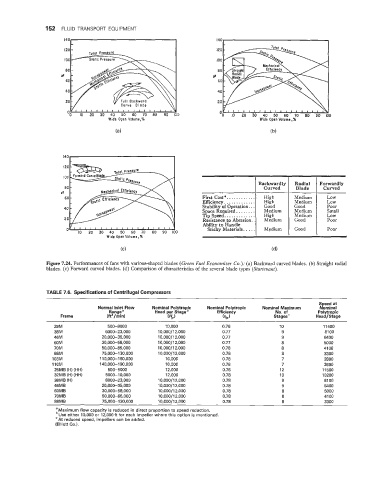

Figure 7.24. Performances of fans with various-shaped blades (Green Fuel Economizer Co.): (a) Backward curved blades. (b) Straight radial

blades. (c) Forward curved blades. (d) Comparison of characteristics of the several blade types (Sturtevant).

TABLE 7.6. Specifications of Centrifugal Compressors

Speed Nominal at

Normal Inlet Flow Nominal Polytropic Nominal Polytropic Nominal Maximum Polytropic

Rangea Head per Stage Efficiency No. of

Frame (ft3/min) (H,) blP) Stages" Head/Stage

29M 500-8000 10,000 0.76 10 1 1500

38M 6000-23,000 10,000/12,000 0.77 9 8100

46M 20,000-35,000 10,000/12,000 0.77 9 6400

60M 30,000-58,000 10,000/12,000 0.77 8 5000

70M 50,000-85,000 10,000/12,000 0.78 8 41 00

88M 75,000-1 30,000 10,000/12,000 0.78 8 3300

103M 11 0,000-1 60,000 10,000 0.78 7 2800

110M 140,000-1 90,000 10,000 0.78 7 2600

25MB (H) (HH) 500-5000 12,000 0.76 12 11 500

32MB (H) (HH) 5000-1 0,000 12,000 0.78 10 10200

38MB (HI 8000-23,000 10,000/12,000 0.78 9 81 00

46MB 20,000-35,000 10,000/12,000 0.78 9 6400

60MB 30,000-58,000 10,000/12,000 0.78 8 5000

70MB 50,000-85,000 10,000/12,000 0.78 8 4100

88MB 75,000-130,000 10,000/12,000 0.78 8 3300

"Maximum flow capacity is reduced in direct proportion to speed reduction.

bUse either 10,000 or 12,000ft for each impeller where this option is mentioned.

'At reduced speed, impellers can be added.

(Elliott Co.).