Page 356 - Chemical process engineering design and economics

P. 356

Separator Design 335

After calculating the minimum reflux ratio and the minimum number of stages,

calculate the optimum or actual reflux ratio. According to Henley and Seader [31]

for a fractionator containing a large number of stages, RQ / RM ~ 1-10, but for a

small number of stages RQ/ RM « 1.50. In between, use a reflux ratio of RQ / RM

= 1.30. Rather than use a rule-of-thumb, we will use the graphical correlation

developed by Van Winkle and Todd [40] from computer calculations. Alterna-

tively, calculate the optimum reflux ratio from Equation 6.27.5, which was devel-

oped by Olujic [41] by curve fitting Van Winkle and Todd's correlation.

Gilliland [42] correlated the number of equilibrium stages with the mini-

mum number of stages, calculated from the Fenske Equation. Gilliland plotted Y e,

defined by Equation 6.27.9, against X,,, defined by Equation 6.27.10. Gilliland's

correlation has been curve fitted by several equations but the simplest of these

equations is McCormick's [43] equation, given by Equation 6.27.8. Oliver [44]

pointed out that Gilliland's correlation leads to large errors when the number of

stages in the stripping section is much larger than the number of stages in the en-

riching section. Gilliland's correlation requires that the feed be introduced at the

optimum stage, calculated from Equation 6.27.12, an empirical equation devel-

oped by Kirkbride [45].

The actual number of stages is equal to the number of equilibrium stages

divided by the fractionator efficiency(overall column efficiency). Although the

tray efficiency will vary, we will use the fractionator efficiency. The fractionator

efficiency is obtained from the O'Connel correlation given in Figure 6.17. Vital et

al. [46] have reviewed and tabulated fractionator and absorber efficiencies for

many systems. These data may help to arrive at a reasonable fractionator effi-

ciency.

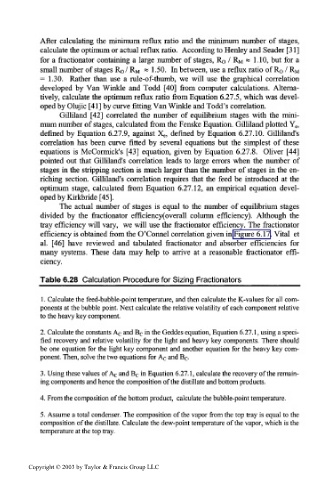

Table 6.28 Calculation Procedure for Sizing Fractionators_________

1. Calculate the feed-bubble-point temperature, and then calculate the K-values for all com-

ponents at the bubble point. Next calculate the relative volatility of each component relative

to the heavy key component.

2. Calculate the constants A c and B c in the Geddes equation, Equation 6.27.1, using a speci-

fied recovery and relative volatility for the light and heavy key components. There should

be one equation for the light key component and another equation for the heavy key com-

ponent. Then, solve the two equations for AC and B c.

3. Using these values of A c and B c in Equation 6.27.1, calculate the recovery of the remain-

ing components and hence the composition of the distillate and bottom products.

4. From the composition of the bottom product, calculate the bubble-point temperature.

5. Assume a total condenser. The composition of the vapor from the top tray is equal to the

composition of the distillate. Calculate the dew-point temperature of the vapor, which is the

temperature at the top tray.

Copyright © 2003 by Taylor & Francis Group LLC