Page 358 - Chemical process engineering design and economics

P. 358

Separator Design 337

erations affect the spacing. For example, when separating oxygen and nitrogen

from liquid air, heat transferred to the fractionator from the surroundings must be

minimized, and thus, the fractionator surface area must be a minimum. This con-

sideration results in a tray spacing of as low as 6.0 in (0.152 m) [48].

The height of a packed fractionator is equal to the number of equilibrium

stages times the height equivalent to a theoretical stage (HETS). Although this

method is not rigorous, Ulrich [50] remarked that it is disquieting to find that the

HETS does not vary much in commercial columns after having spend hours learn-

ing to calculate combined mass transfer coefficients. For fractionator diameters

less than 0.5 m (1.64 ft), Frank [33] recommends the rule of thumb that D =

HETS, and for column diameters greater than 0.5 m (1.64 ft), the HETS is given

by Equation 6.27.26 [50].

Besides the height occupied by trays or packing, additional height is needed

at the top and bottom of the fractionator. Henley and Seader [31] recommend

adding 4.0 ft ( 1.22 m) to the top of the fractionator to minimize entrainment and

10.0 ft (3.05 m) to the bottom for surge capacity. For fractionators or absorbers of

about three feet in diameter, Walas [51] recommends that 4.0 ft (1.22 m) be added

to the top and 6.0 ft (1.83 m) to the bottom of the column. Ulrich [50] recom-

mends that the volume below the bottom tray be sufficient for 5 to 10 min surge

time which results in 1.0 to 4.0 m (3.28 to 13.1 ft) of additional height. Thus, as

an approximation add 4.0 ft (1.22 m) to the top of the column and a surge height,

L s, to the bottom of the column. The surge height is calculated from Equation

6.27.16. The diameter of a fractionator or absorber is usually limited to 13.0 ft

(3.96 m) and the length to about 200 ft (60.9 m) because of shipping limitations.

If lengths larger than 200 ft (60.9 m) are necessary, then two vessels in series

could be used. Exceptions to rules-of-thumb sometimes occur. One of the largest

fractionators - made in Europe - is 356 ft (109 m) high and 21.0 ft (6.40 m) in

diameter [47]. Another large ethylene fractionator built in Deer Park, TX, is 328 ft

(100 m) high by 18 ft (5.49 m) in diameter [9]. This column was fabricated in

sections and assembled at the site.

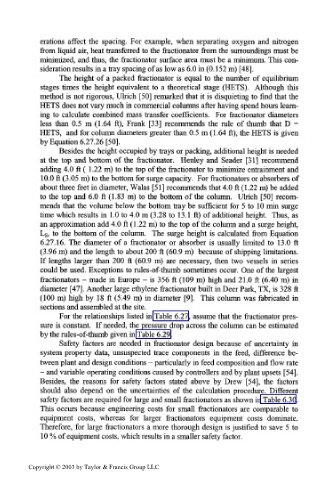

For the relationships listed in Table 6.27, assume that the fractionator pres-

sure is constant. If needed, the pressure drop across the column can be estimated

by the rules-of-thumb given in Table 6.29.

Safety factors are needed in fractionator design because of uncertainty in

system property data, unsuspected trace components in the feed, difference be-

tween plant and design conditions - particularly in feed composition and flow rate

- and variable operating conditions caused by controllers and by plant upsets [54].

Besides, the reasons for safety factors stated above by Drew [54], the factors

should also depend on the uncertainties of the calculation procedure. Different

safety factors are required for large and small fractionators as shown in Table 6.30.

This occurs because engineering costs for small fractionators are comparable to

equipment costs, whereas for larger fractionators equipment costs dominate.

Therefore, for large fractionators a more thorough design is justified to save 5 to

10 % of equipment costs, which results in a smaller safety factor.

Copyright © 2003 by Taylor & Francis Group LLC