Page 441 - Chemical process engineering design and economics

P. 441

422 Chapter 8

ween parts, and thus it is very reliable. The life of this valve is prolonged because

the ball continually rotates and thus wears evenly. An example of the use of a

check valve is when pumping a liquid into a pressurized vessel. If the power de-

livered to a pump fails, the liquid in the vessel will flow back through the feed line

and damage the pump. To prevent this, install a check valve in the feed line.

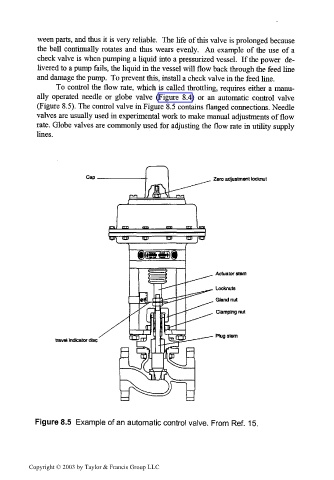

To control the flow rate, which is called throttling, requires either a manu-

ally operated needle or globe valve (Figure 8.4) or an automatic control valve

(Figure 8.5). The control valve in Figure 8.5 contains flanged connections. Needle

valves are usually used in experimental work to make manual adjustments of flow

rate. Globe valves are commonly used for adjusting the flow rate in utility supply

lines.

Zero adjustment locknut

travel Indicator disc

Figure 8.5 Example of an automatic control valve. From Ref. 15.

Copyright © 2003 by Taylor & Francis Group LLC