Page 446 - Chemical process engineering design and economics

P. 446

Design of Flow Systems 427

Reactarrt2

H——M—4P 1

(fp^ ——Safety Valve Coolant In

tx) On-Off Valve V^l^.^

M ThrotllinB Valve

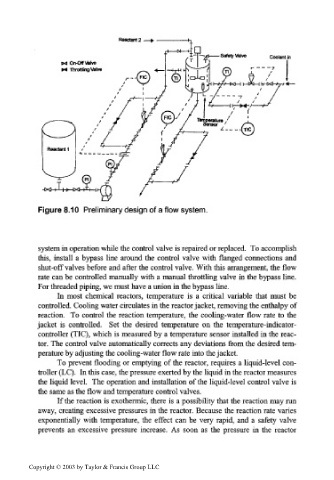

Figure 8.10 Preliminary design of a flow system.

system in operation while the control valve is repaired or replaced. To accomplish

this, install a bypass line around the control valve with flanged connections and

shut-off valves before and after the control valve. With this arrangement, the flow

rate can be controlled manually with a manual throttling valve in the bypass line.

For threaded piping, we must have a union in the bypass line.

In most chemical reactors, temperature is a critical variable that must be

controlled. Cooling water circulates in the reactor jacket, removing the enthalpy of

reaction. To control the reaction temperature, the cooling-water flow rate to the

jacket is controlled. Set the desired temperature on the temperature-indicator-

controller (TIC), which is measured by a temperature sensor installed in the reac-

tor. The control valve automatically corrects any deviations from the desired tem-

perature by adjusting the cooling-water flow rate into the jacket.

To prevent flooding or emptying of the reactor, requires a liquid-level con-

troller (LC). In this case, the pressure exerted by the liquid in the reactor measures

the liquid level. The operation and installation of the liquid-level control valve is

the same as the flow and temperature control valves.

If the reaction is exothermic, there is a possibility that the reaction may run

away, creating excessive pressures in the reactor. Because the reaction rate varies

exponentially with temperature, the effect can be very rapid, and a safety valve

prevents an excessive pressure increase. As soon as the pressure in the reactor

Copyright © 2003 by Taylor & Francis Group LLC