Page 279 - Compression Machinery for Oil and Gas

P. 279

264 SECTION II Types of Equipment

seal is used, the seal is usually fed by the common oil system. When higher

safety requirements call for a double mechanical seal, it is typical for a sep-

arate oil system to be used for the driveshaft seal. This allows better control

of the temperature, pressure, and flow of the oil to the seal, and also ensures

that any oil leakage on the atmospheric side of the seal does not contain any

process gas.

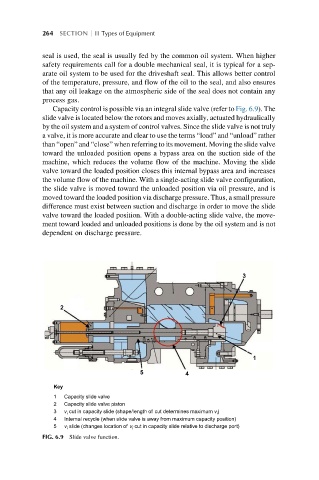

Capacity control is possible via an integral slide valve (refer to Fig. 6.9). The

slide valve is located below the rotors and moves axially, actuated hydraulically

by the oil system and a system of control valves. Since the slide valve is not truly

a valve, it is more accurate and clear to use the terms “load” and “unload” rather

than “open” and “close” when referring to its movement. Moving the slide valve

toward the unloaded position opens a bypass area on the suction side of the

machine, which reduces the volume flow of the machine. Moving the slide

valve toward the loaded position closes this internal bypass area and increases

the volume flow of the machine. With a single-acting slide valve configuration,

the slide valve is moved toward the unloaded position via oil pressure, and is

moved toward the loaded position via discharge pressure. Thus, a small pressure

difference must exist between suction and discharge in order to move the slide

valve toward the loaded position. With a double-acting slide valve, the move-

ment toward loaded and unloaded positions is done by the oil system and is not

dependent on discharge pressure.

3

2

1

5

4

Key

1 Capacity slide valve

2 Capacity slide valve piston

3 v i cut in capacity slide (shape/length of cut determines maximum v i )

4 Internal recycle (when slide valve is away from maximum capacity position)

5 v i slide (changes location of v i cut in capacity slide relative to discharge port)

FIG. 6.9 Slide valve function.